Hekinan Thermal Power Station Our Commitment to the Safe Use of Fuel AmmoniaOur Company / Power Station List

Innovation

A First-in-the-World Project Underway in Hekinan

Approximately 80% of Japan's current energy requirements are met through thermal power generation using fossil fuels. At the same time, approximately 40% of the country's CO2 emissions derive from thermal power generation. As Japan's largest power generation company, we are committed to the JERA Zero CO2 Emissions 2050 roadmap for achieving net-zero CO2 emissions from our operations by 2050.

Toward Carbon-Free Thermal Power Generation

As a first step toward achieving carbon-free thermal power generation, JERA is working on the use of ammonia as fuel at the Hekinan Thermal Power Station in the city of Hekinan in Aichi Prefecture. Boasting a total output of 4.1 million kW, the Hekinan station is the largest coal-fired power station in Japan and one of the largest in the world, providing stable power to the Chubu region and surrounding areas . In March 2024, we will begin first-in-the-world demonstration testing* at Hekinan Thermal Power Station to establish technology for generating electricity by substituting 20% of fuel coal with ammonia.

- "R&D and Demonstrations on Technologies for Ammonia Co-firing Thermal Power Generation," subsidized by the New Energy and Industrial Technology Development Organization (NEDO)

Using Fuel Ammonia at a Coal-Fired Power Plant: Advantages and Prospects:

Coal-fired power plants burn finely pulverized coal to create steam, which then drives turbines to generate electricity. Thermal power generation emits CO2 that contributes to global warming, and our focus here is on a method to gradually substitute fuel coal with ammonia, which doesn't produce CO2 when burned. In addition, because ammonia and coal are compatible fuel sources with similar combustion rates, substituting coal with ammonia reduces CO2 emissions without affecting power output.

Because this approach can be pursued using existing facilities , it is also relatively quick and inex pensive to implement. By gradually increasing the proportion of fuel ammonia used, we ultimately aim to transition to ammonia-only power generation.

Comprehensive Fuel Ammonia Infrastructure

Fuel ammonia, cooled to approximately -33°C and liquefied, is transported via specially designed ships. After reaching Hekinan Thermal Power Station, it is received and stored in the same way in dedicated storage tanks. We implement comprehensive measures to ensure the safe operation of our storage tanks and other fuel ammonia facilities.

Ammonia Tank (3D Rendering)

Ammonia-Already a Versatile Player Across Industry

Ammonia is widely used not only as a raw material for producing fertilizer but also in the chemical industry and as a refrigerant in commercial freezers. Because it is also used to remove pollutants from exhaust gases at thermal power plants, at JERA we have an extensive track record handling ammonia.

Stable combustion of ammonia as a fuel for thermal power generation has also been widely demonstrated in laboratory tests by boiler manufacturers and research institutions.

Our Safety Initiatives

In handling fuel ammonia, we are committed to maintaining safe operations at our facilities to ensure peace of mind not only for the local community but also for power plant employees. Efforts to prevent ammonia leaks include robust safety designs that prevent facilities damage due to earthquakes, high tides, tsunamis, and floods, and we will remain vigilant in implementing measures to prevent equipment malfunction and human error.

We also ensure safe and secure operations by establishing systems for the early detection of facilities anomalies and by continuously refining our emergency response manuals and training.

To prepare for the unlikely event of a leak, we also take measures such as collaborating with the Hekinan City Fire Department and maintaining close lines of communication with local authorities.

Safety

Setting the Bar for Safety: World-Leading Preparedness for Every Contingency

① lncident Prevention

Seismic Design

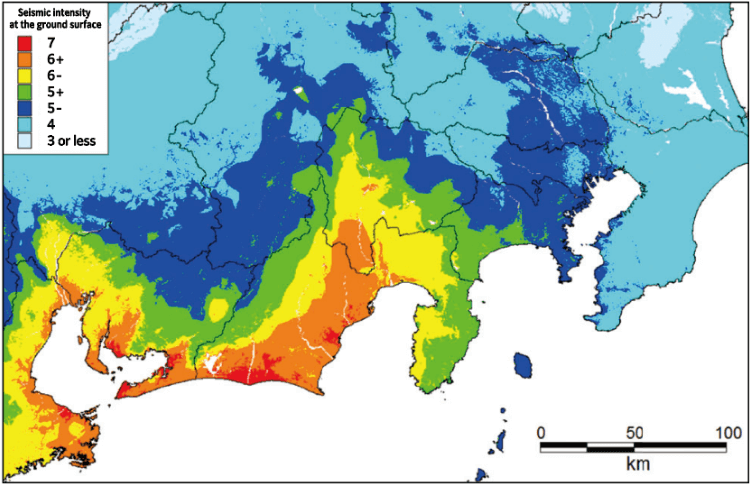

At JERA, we take all possible measures to ensure that our facilities remain undamaged in the event of a natural disaster. To address earthquakes, we have designed robust, safe facilities to ensure that foundations, tanks, and piping are strong enough to handle a potential megathrust earthquake along the Nankai Trough.

Distribution of seismic intensity at the ground surface (Nankai Trough megathrust earthquake)

High Tide, Flood, and Tsunami Countermeasures

We have designed our facilities to withstand the highest storm surge to date, recorded during the lse Bay Typhoon of 1959, as well as the severest high tides, floods, and tsunamis anticipated in the future.

② EarlyO Detection & Resolution

In addition to daily patrols and regular equipment inspections, we conduct 24-hour real-time remotemon itoring of operating conditions and potential gas leaks. In the event of an anomaly, an alarm is triggered and operators, following their operating manuals and extensive training respond immediately to ensure quick resolution .

Central Control Room

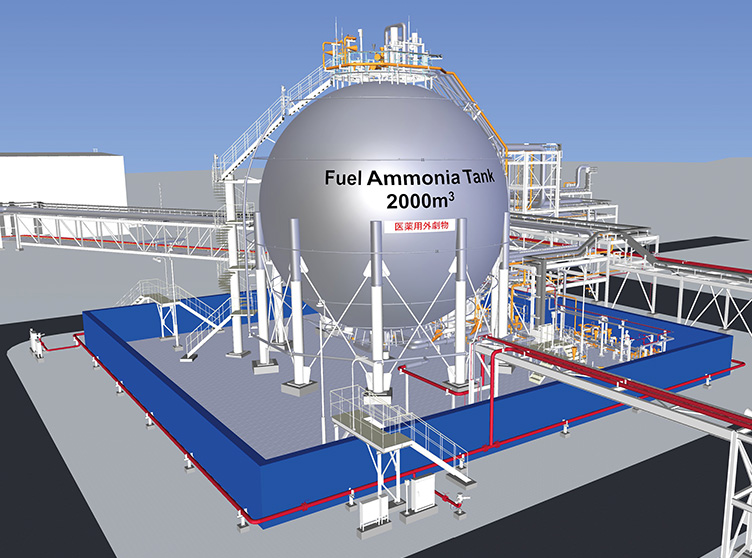

③ Containment Measures

Ammonia is highly soluble in water, so in the unlikely event of a leak, water is sprayed to absorb the ammonia gas and prevent it from spreading. Tanks are installed within containment dikes that act as fences to prevent liquids from escaping, so the water used to absorb the ammonia is retained within these dikes for prompt recovery.

Dike

"As members of the community, safety is our highest priority."

As part of our efforts to achieve a decarbonized society, first-in-the-world demonstration testing is underway at Hekinan Thermal Power Station to transition the power plant's fuel from coal to ammonia, which emits no CO2 when burned. At JERA, we have extensive experience handling ammonia at thermal power plants, but we are now taking even greater precautions, implementing measures to prevent and detect potential anomalies in advance and to contain any leaks should they occur. As members of the community, safety is our highest priority.

Katsuya Tanigawa

General Manager

Hekinan Thermal Power Station

JERA Co., Inc.