SafetySustainability

Safety Philosophy

The Mission of the JERA Group is to provide cutting-edge solutions to the worldʼs energy issues. To fulfill this mission, it is essential to conduct our business activities safely and supply energy in a stable manner

To that end, the JERA Group will develop its business activities based on the premise of “Safety First" in its entire supply chain from fuel upstream investment/procurement to sales, and will work on further safety measures to ensure that everyone in society can have peace of mind.

Safety Policies

Based on the Safety Philosophy, the JERA Group will work on the following policies:

- Create a safe, healthy and comfortable work environment.

- Observe safe and appropriate operating procedures and rules.

- Design, operate, and maintain facilities with safety in mind.

Principles of Conduct

To realize the Safety Philosophy and the Safety Policies, each and every officer and employee will act in accordance with the following principles of conduct:

- Work together across organizations and responsibilities to ensure safety.

- When in doubt, always choose the safer option.

- Make continuous efforts and initiatives to ensure safety.

Fundamental Approach

Safety: The Highest Priority in Everything We Do

Our mission is to provide cutting-edge solutions to the world's energy issues. Power generation and fuel facilities operate under high pressures and temperatures, handling many hazardous materials. It is essential to eliminate accidents among all personnel involved in facility operation and maintenance and deliver energy in a safe and stable manner.

That is why we operate on the basic premise of safety first throughout our supply chains, from upstream fuel procurement to electricity sales, in accordance with our safety philosophy.

Safety Activities Reaching All Involved in Our Operations

They require the collaboration of group and partner companies in the workplace, which is why our safety activities cover everyone involved in the JERA Group's operations. As the business domain grows, we intend to expand our business areas including those overseas, all while giving the highest priority to safety.

Working with Group Companies and Partners to Foster an Integrated Safety Culture

Realizing our safety goals means making sure everyone involved in the JERA Group's operations is aware of safety as the highest priority, including at our group companies and business partners.

The JERA Safety Vision was established to give everyone, regardless of nationality, race, or affiliation, the ability to talk about safety goals using a common language. We are also developing activities to build a culture of safety that brings JERA employees together with everyone from group companies and partner companies.

In Pursuit of Zero Accidents

Kazuyuki Arita

Executive Officer, Head of the General Affairs Division

We are also exploring new technologies, such as the fuel conversion to hydrogen & ammonia. As the workplace environment undergoes significant changes, it might be difficult to achieve zero accidents across all our business sites by simply maintaining the status quo in our safety activities.

Therefore, we are committed to further refining the safety management and technologies we have developed over many years in Japan, while also incorporating global safety management techniques and cutting-edge safety technologies to enhance their effectiveness. At the same time, we are working to foster a safety culture where each employee actively engages in raising their own safety awareness and ensuring both their own safety and that of their colleagues. Through these activities, we aim to reduce the number of accidents to zero and earn people’s trust as a dependable member of the community.

Our Safety Action Strategy

A Safety Action Strategy to Implement Our Safety Philosophy

In 2021, we underwent a safety activity assessment by a third party and received recommendations focusing on leadership, organizational structure, and business operations as key areas for improvement to implement our safety philosophy.

To reflect these recommendations, we formulated our Safety Action Strategy in FY2022 to set medium-term action items for our group's safety and will formulate annual action plans based on this strategy.

| Our Safety Action Strategy for FY2023–25 | Major FY2023 Initiatives |

|---|---|

| Leadership Continuous leadership from management and raising individual safety awareness |

|

| Organizational System Constructing a robust management system to lead our safety efforts |

|

| Measures Effective safety activities to address changes in the environment |

|

Featured

Annual Safety Awards

During the 2023 awards ceremony, a total of 47 organizations and 32 individuals from sites in Japan and overseas were honored, including the Mekong Energy's Phu My 2.2 Power Plant in Vietnam and TeaM Energy in the Philippines.

Many of the award winners commented that learning about the initiatives of other locations was helpful and motivating and appreciated that the awards led to the sharing of safety activities and culture.

Safety Promotion System

Establishment of a Safety Promotion System with Management-Level Participation

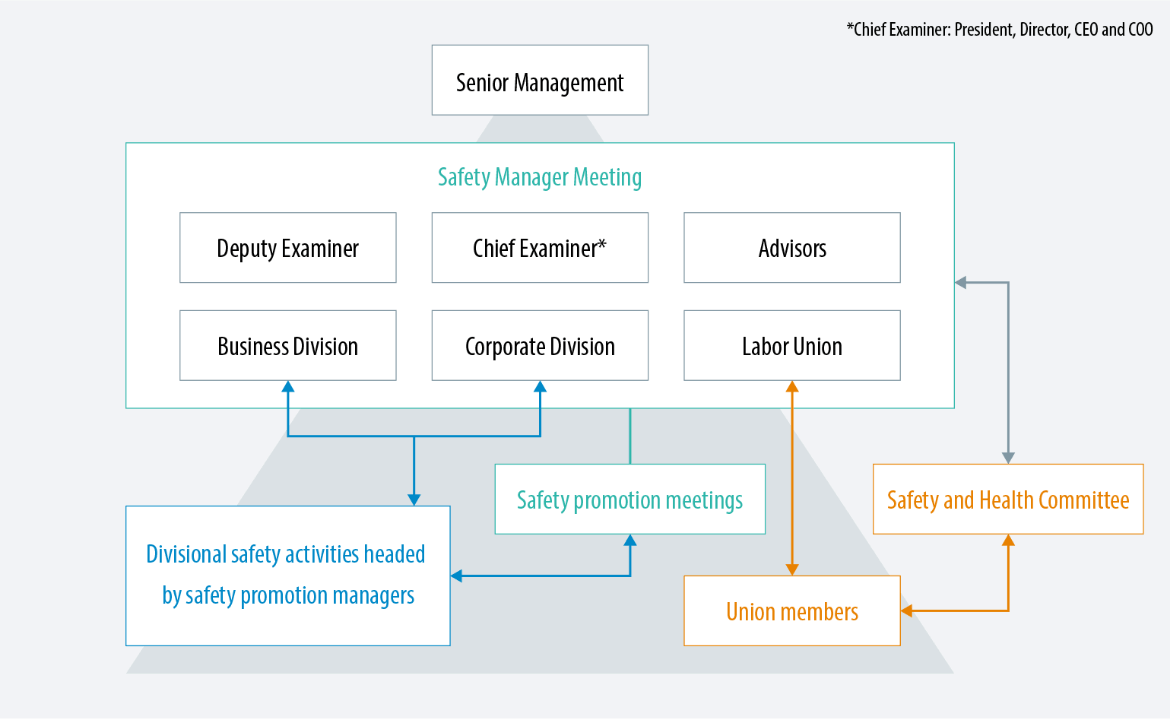

To advance company-wide safety initiatives and reinforce our safety promotion system, we established the Safety Manager Meeting, which is chaired by the President, Director, CEO and COO and attended by safety promotion leaders from each division.

As the number of our overseas subsidiaries increases, we plan to establish a group-wide safety promotion system that includes affiliated companies.

JERA's Safety Promotion Structure(as of April 1, 2024)

Pragmatic Discussions at the Safety Manager Meeting

The safety manager meeting includes the labor union chairperson representing employees and external experts who offer third-party perspectives on the company's safety measures.

In FY2023, eight sessions focused on specific measures to achieve zero accidents. The discussions assessed the thoroughness of the investigation into the fatal accident that occurred during the fiscal year and evaluated the effectiveness of preventive measures. They also highlighted the key steps necessary to ensure that individuals can consistently prioritize safety in emergency situations.

Accident Prevention Efforts

Expanding Integrated Safety Activities in Japan and Abroad to Ensure Zero Accidents in the Workplace

At our overseas power plants, we also implement safety activities tailored to each workplace while complying with the safety laws and regulations of each country and region.

We will continue to share safety initiatives from these diverse workplaces internally to establish common codes of conduct for the entire JERA Group.

Safety patrol at Mekong Energy's Phu My 2.2 Power Plant (Vietnam)

Facility Safety Measures for Emergency Readiness

We must be able to bring facilities back online quickly, even in the event of natural disasters or other major emergencies. We, therefore, manage our thermal power plants appropriately in accordance with all relevant laws and regulations, and conduct drills and training in cooperation with local communities to be fully prepared for any emergencies.

Earthquake Countermeasures

We design and build new thermal power plants in keeping with all relevant earthquake laws and regulations, as well as the Japan Electric Association Code (JEAC), and conduct periodic facility inspections after completing construction to ensure earthquake resistance. In addition, we take into account any earthquakes announced by official government bodies such as the Cabinet Office, evaluating the seismic resistance of key facilities and implementing measures such as seismic reinforcement to avoid long-term shutdowns due to damage or destruction.

Whenever earthquake predictions or other new information becomes available, we will act on these insights to assess the adequacy of our current earthquake preparedness and implement any required measures.

Safety Measures in LNG Handling

Our thermal power plants and LNG terminals handle vast quantities of LNG, so in preparation for the unlikely event of an LNG leakage, we implement safety measures based on the following three concepts: (1) leakage prevention, (2) early leakage detection, and (3) prevention of leakage expansion. We also make considerations for the handling of fire. For example, we adopted explosion-proof structures for electrical equipment surrounding LNG facilities and restricted the use of products that might cause fire by designating control zones.

Safety Record

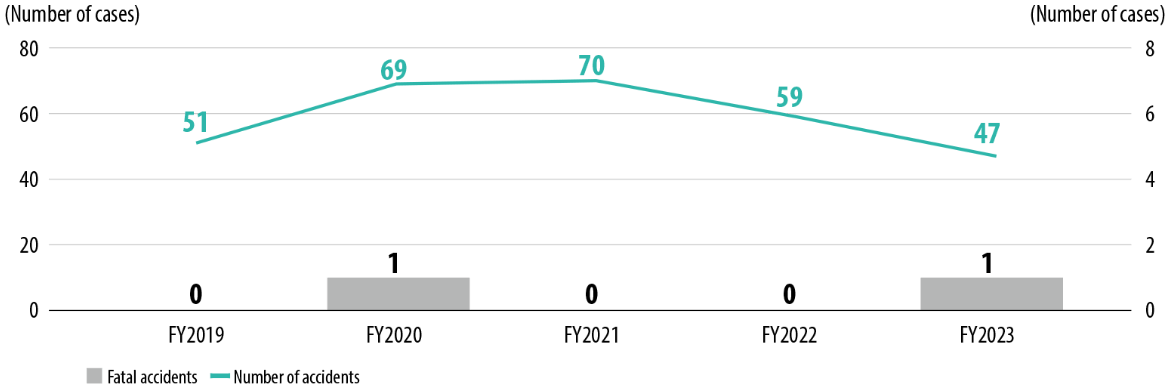

Safety Target (KPI): Zero fatalities

We have set "zero fatalities" as a KPI and are engaged in a range of activities to achieve this goal.

As a result, the total number of accidents at the principal entity of JERA in FY2023 was the lowest since the integration of thermal power generation operations in FY2019. However, one fatal accident occurred at a group company in Japan in FY2023.

Number of Accidents*

Note: The number of accidents includes employees of our company and our group's contractors and subcontractors, and includes accidents not accompanied by lost workdays.

Thoroughly Implementing Measures to Prevent the Recurrence of Fatal Accidents

The day after the fatal accident, the President, Director, CEO and COO sent a message to the entire group emphasizing the importance of strict adherence to basic safety practices. The causes of the accident were investigated and preventive measures were reviewed at the safety manager meeting. These measures were subsequently implemented across all business sites.

We will continue to monitor the implementation and effectiveness of these preventive measures as we strive to develop even more robust solutions to prevent future accidents.