Treatment of Coal AshSustainability / Proper Treatment of Waste

When coal is combusted, about 10% of coal ash is generated, and effective use of large amounts of coal ash becomes an issue. For example, units 1 to 5 of the Hekinan Thermal Power Station at our company use about 10 million tons of coal every year. This means 1 million tons of coal ash is calculated to be generated every year.

Coal ash has superb material characteristics such as (1) fine particles, (2) light weight, and (3) increased strength. In order to effectively use limited resources, a variety of recycling methods are used.

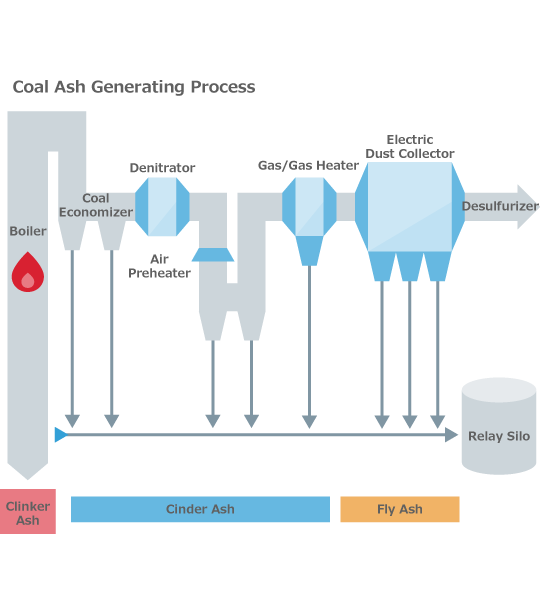

Coal Ash Generation Process

Coal ash can be broadly classified into “fly ash” and “clinker ash”. Let us look at how “fly ash” and “clinker ash” are generated by coal-fired thermal power stations.

(1) At coal-fired thermal power station, coal broken down into powder form is combusted in a boiler, and that energy is converted into electricity. The coal ash particles melted by this combustion float in hot combustion gases; the particles become vitreous and round when the temperature drops outside the boiler and are collected by electric precipitators. This is generally called “fly ash”.

(2) The quality of this fly ash is managed online by a “quality management system” that analyzes the characteristics of the coal ash, sifts according to usage, and aligns the size of the particles to store in each silo.

(3) Meanwhile, the particles of the coal ash in the boiler adhere to each other, form a lump with many holes, and drop into a water tank (clinker hopper) on the bottom of the boiler. These lumps fall and are deposited in the water tank (clinker hopper) and are crushed into a sandy state; this is called “clinker ash”. Normally clinker ash, after it is dried out in a hydrating tank, is stored in this sandy state.

What is Fly Ash?

The main components of fly ash are silica and alumina, the same components as soil. When mixed with cement, it reacts with the calcium hydroxide generated by hydration of the cement (formation of a new compound through the reaction of water and cement) and works to improve durability and water impermeability. Also, because fly ash is made of small circular particles, when it is mixed in concrete, it has excellent features for improving the fluidity of the concrete.

What is Clinker Ash (Bottom Ash)?

Clinker ash, formed from ash melted red hot in a high-temperature boiler, dropped to the bottom of the water tank, and immediately cooled and crushed with a crusher, is a sand state with an adjusted particle size. The main components of clinker ash are “silica” and “alumina”, the same components as fly ash. As the surface of the clinker ash has many small holes, it has excellent features for water retention, water drainage, and breathability.

Effective Use of Coal Ash

Among our thermal power stations, coal-fired thermal power stations use coal ash effectively.

- Coal ash is transported by sea or land to cement factories and effectively used as an ingredient for cement.

- Coal ash is used effectively as construction material.