Initiatives at Thermal Power Plants in JapanSustainability

JERA has been delivering electric power for years through power plant and fuel terminal operation and maintenance. We coexist with local communities and will continue to support manufacturing and provide a comfortable way of life in our communities.

Kawasaki Thermal Power Station

| Power generation equipment | Output(MW) | Fuel | Start of operation | Type of power generated | |

|---|---|---|---|---|---|

| Group 1 | Unit 1-1 | 500 | LNG | February 2009 | Combined cycle |

| Unit 1-2 | 500 | June 2008 | |||

| Unit 1-3 | 500 | June 2007 | |||

| Group 2 | Unit 2-1 | 500 | February 2013 | ||

| Unit 2-2 | 710 | January 2016 | |||

| Unit 2-3 | 710 | June 2016 | |||

Coexisting with Local Communities

Supplying Heat to Neighboring Factories

Steam supply pipe

Power Plant Tours

Power plant tour

Contributing to Stable Supply

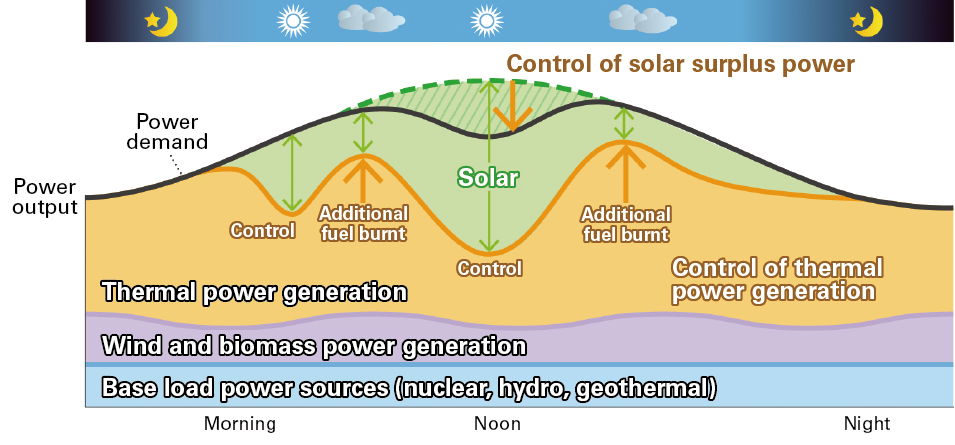

Combined cycle power generation fueled by LNG is highly adaptive to load changes in electricity demand compared to other forms of thermal power generation. This means that output can be adjusted significantly in a short period of time; for example, output can be raised from 50% to full capacity in as little as 10 minutes.

Currently, Kawasaki Thermal Power Station also plays a role in adjusting output according to fluctuations in power generation from renewable energy sources, which are affected by weather and other factors, thereby contributing to a stable supply of electricity on a daily basis.

Source: “10 questions for understanding the current energy situation in FY 2021 version,” available on the Agency for Natural Resources and Energy website

Kawasaki Thermal Power Station was the first power plant in eastern Japan to implement the Toyota-style kaizen system for inspection and maintenance operations to improve power generation facility performance. The plant has achieved a significant reduction in maintenance time through three basic pillars for optimizing regular inspections: (1) off-line setup, (2) simultaneous operation, and (3) refinement.

This system enables us to promote the operating rate of the highly efficient Kawasaki Thermal Power Station and reduce operations at inefficient thermal power plants, thereby achieving overall optimization of operations at our thermal power generation facilities and contributing to the reduction of fuel costs and CO2 emissions. JERA was the first power generation company to adopt this kaizen approach internally, and now, after further study, we have developed our own “JERA-style kaizen” to further improve on this approach.

Equipment inspection

Taketoyo Thermal Power Station

The Taketoyo Thermal Power Station is located in a temperate natural environment at the center of the Chita Peninsula in Aichi Prefecture, at the mouth of Kinuura Bay, northwest of Mikawa Bay.

Unit 1 started commercial operation in 1966, with Units 2 through 4 following in 1972, and they each played a major role in providing a stable supply of electric power to the Chubu region. The plant has since been converted into a high-efficiency coal-fired power plant. Beginning in August 2022, it incorporated co-firing of woody biomass fuel to offer a stable long-term supply of electric power, reduce the cost of power generation, and improve environmental performance with the introduction of state-of-the-art equipment.

| Power generation equipment | Output(MW) | Fuel | Start of operation | Type of power generated |

|---|---|---|---|---|

| Unit 5 | 107 | Coal Woody biomass | August 2022 | Steam power |

Environmental Initiatives

Measures for Dust Control

We are striving to control dust through measures such as adopting an indoor coal storage area designed with the smallest possible openings and using an enclosed structure for our discharge conveyors and fuel-receiving operations.

Measures for Noise Control

We have implemented measures for noise control to protect the surrounding area, including installing noise barriers around boilers, employing low-noise equipment, and installing sounddeadening devices.

Reuse of Coal Ash and Gypsum

We effectively use the coal ash (cinders and particulate matter) generated from burning coal and the gypsum produced by exhaust gas desulfurization equipment as fuel for cement production, material to make building boards, soil improvement additives, and more.

Above: Enclosed conveyor belt

Top right: Indoor coal storage area

Noise barrier

Introduction of Woody Biomass Facilities: Achieving Both a Stable Supply and Reduced Environmental Impact

Taketoyo Thermal Power Station uses highly efficient ultrasupercritical (USC) pressure power generation equipment, the best technology available for coal-fired power generation, and has a capacity of 1,070 MW, one of the largest single-unit outputs in Japan.

We are also working to improve environmental performance by co-firing woody biomass fuel. From the mill pulverizing the fuel into fine powder to the burner serving as combustion equipment, the facilities exclusively use woody biomass, ensuring a high co-combustion ratio (co-firing rate of 17%) and further reducing CO2 emissions (≈ 0.9 million tons per year).

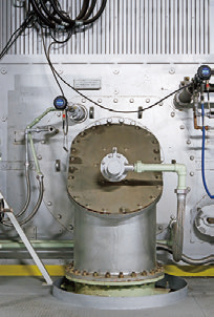

Wood pellet mill

Wood pellet burner

What is woody biomass?

Woody biomass is an environmentally friendly, carbonneutral fuel made from pellets of waste wood generated during sawmilling (wood that cannot be used for construction, furniture, or other such applications). The indoor coal storage area can hold ≈ 0.07 million tons of woody biomass fuel.

Wood pellets

Indoor coal storage area