The Second Memory

A Commitment to Stable Energy Is in Our DNA (Second Half)

27 September 2024

On March 11, 2011, the Great East Japan Earthquake struck. This unprecedented disaster shook Japanese society to its core and fundamentally disrupted stable energy supply in the country. Nuclear power stations throughout Japan were shut down, and some thermal power stations, which served as a backup for nuclear power, suffered devastating damage from the tsunami caused by the earthquake. This led to a severe power shortage. In this time of crisis, the Kashima Thermal Power Station became a ray of hope.

In the second half of this article, we will delve into the chaos immediately following the Great East Japan Earthquake and the intense efforts to secure a stable supply of power by installing new energy sources at the Kashima Thermal Power Station.

>> Read the first half of Part 2: A Commitment to Stable Energy Is in Our DNAINDEX

Major Concerns About Being Unable to Fulfill TEPCO’s Mission

The central control room immediately after the Great East Japan Earthquake on March 11, 2011.

The Great East Japan Earthquake struck on March 11, 2011. The massive earthquake and tsunami forced many power stations, including TEPCO’s Fukushima Daiichi Nuclear Power Station, to shut down. This resulted in a severe power shortage in the Tohoku and Kanto regions.

In response, TEPCO worked to secure stable power supply by borrowing electricity from other power companies as the national government urged the public and businesses to conserve electricity. However, the supply capacity was tight compared to the anticipated power usage. Thus, the major decision had to be made to implement planned power outages in Tokyo metropolis and eight prefectures from March 14.

Toshihiro Sano (who later became Chairman of JERA) was an executive officer at TEPCO and in charge of its thermal power department at the time. He recalls, “TEPCO’s mission is to provide stable energy supply. It’s practically embedded in the DNA of the employees. But this unprecedented situation jolted our raison d’etre. A sense of crisis spread through the company that if we had to implement planned power outages twice, it would be the end of us.”

Sano recalls, “We had to push forward, regardless of whether we thought we could succeed.”

Summer, the season when electricity demand reaches its peak, was approaching. There were also no prospects for the recovery of Fukushima Daiichi. Given the supply capacity at the time, a second round of planned power outages seemed unavoidable. As anxiety grew day by day, thermal power provided a ray of hope. The restoration of the Kashima Thermal Power Station, with its large power generation capacity, seemed particularly promising.

Sano says, “At that time, TEPCO’s top management was fully occupied with handling the Fukushima Daiichi crisis, so I was left with full responsibility for the thermal power sector. My top priority was to secure power supply and avoid planned power outages. The burden of this responsibility caused many sleepless nights, but I knew there was no use in worrying endlessly. I resolved to give it my all, and if it still didn't work out, I would accept the consequences. With that resolve, I took charge of the recovery efforts.”

Kashima Thermal Power Station: At the Forefront of Recovery Efforts

Units 2, 3, 5, and 6 at the Kashima Thermal Power Station were shut down due to the earthquake, while Units 1 and 4 were rendered inoperable due to liquefaction and flooding caused by the tsunami. Sano recalls, “I felt bad about giving Kashima such an impossible challenge.

I told the station manager at the time, ‘I’m entrusting the entire recovery to you, but you have less than a month to get it back online. Tell me if you need anything.’ Having experience in the field myself, I knew that recovery would usually take over a year. But I made that impossible request anyway.”

Photos of the power station immediately after the earthquake, one month later, and in April 2021. Equipment sank after the earthquake due to liquefaction but was restored a month later.

However, what happened next defied all expectations. With staff, partner companies, and manufacturers working together around the clock, Unit 4 at the Kashima Thermal Power Station resumed operation on April 1, just 21 days after the earthquake. This was followed by the full restoration of all units within just two months. Sano describes this recovery as nothing short of a "miracle."

“What made this possible was the dedication of everyone involved who gave their all for Kashima. Thanks to the Kashima Thermal Power Station’s swift recovery, other damaged power stations like Hitachinaka Thermal Power Station and Hirono Thermal Power Station were inspired to push forward with their own efforts. I cannot express my gratitude enough.”

Before and after photos showing restoration of the disaster-damaged firefighting seawater pump structure.

Additionally, emergency power sources like diesel engines and gas turbines were gathered from both within Japan and abroad, helping to avoid planned outages during the summer of 2011. However, due to the ongoing uncertainty surrounding power supply in the wake of the Fukushima Daiichi accident, it became clear that an increase in power generation capacity was essential for the future. That summer, it was decided to urgently install Group 7 as a new power source on the Kashima Thermal Power Station premises.

Photo of Group 7, which continues to balance power supply and demand.

Significant Process Delays and Major Construction

There were two goals for the construction of Group 7. The first was to install three gas turbines and have them up and running by July 2012. The second was to build a combined cycle power generation system, involving the addition of steam turbines and exhaust heat recovery steam boilers, with a target to start operations by the summer of 2014.

In July 2011, a special team called the Kashima Thermal Power Plant Construction Office was formed to work on building Group 7. The team members included Shintaro Uzawa, who was appointed deputy director (now Managing Director of Tokyo Power Technology), Hiroaki Kamei, an expert in electrical equipment and control systems (now Executive Officer, Head of the Digital Power Plant Promotion Group, O&M Engineering Advanced Technology Division, JERA), experienced members from overseas businesses and thermal power projects, and young employees.

“It was full of unprecedented challenges,” recalls Uzawa when looking back on the construction.

As deputy director, Uzawa was dedicated to coordinating with the surrounding local governments and residents.

He continues, “It was unprecedented to run gas turbines while carrying out combined cycle construction. Plus, the timeline was extremely tight. This type of work would normally take six years, but we had to finish it in three. It was also unprecedented that the gas pipeline needed to supply utility gas as fuel was not even completed when we started construction.”

Indeed, the construction faced severe difficulties right from the start. Kamei reflects, “We couldn’t even get the work off the ground.

After the earthquake, Kamei was involved in the construction of about 300 emergency power supplies.

The only document I received was the basic design on a sheet of A3 paper. Despite being appointed to the project, I had to begin by painstakingly gathering all the basic information needed to proceed with construction.”

The huge amount of work was another difficulty. Initially, the team considered using both utility gas and diesel oil as fuels. The idea was to be able to use diesel oil in case the unfinished utility gas pipeline was not completed in time. As a result, the workload doubled.

Kamei explains, “With just utility gas, we would only need to connect a pipeline, but diesel oil requires building tanks, installing pumps, and other construction work. The time it took to gather information, combined with the process delays caused by the enormous amount of construction work, meant that it was a race against time. There was a possibility that we would not start operations by the required target of July 2012.”

A Decision Amid Mounting Pressure

As the delays worsened in October 2011, Uzawa gathered the construction office team to announce the decision to halt the diesel-related construction work and focus all resources on gas-fired power generation. He was betting on the possibility that the utility gas pipeline could be completed quickly.

Uzawa says, “I had previous experience working in the gas industry and was familiar with how gas companies operate. They are very good at negotiating with local communities and pushing projects forward, so I believed they would get the construction done in time.”

But could they really make it in time? Kamei repeatedly consulted with the machinery group members and the gas company about the installation work for the utility gas pipe and when it would be ready to use, always emphasizing, “We must have the pipeline ready by June 6, when test commissioning will begin.”

Kamei notes, “Gas pipelines are buried underground, so things don’t always go according to plan, such as excavation work. That’s why we conducted thorough interviews with the gas company plus everyone else involved in the construction to ensure there would be no major issues or unexpected incidents. With that confirmation, we decided to go all in on the construction for gas-fired power generation.”

Doing whatever it took to meet its deadlines, TEPCO used Antonov aircraft, among the world’s largest, to speed up the process of transporting electrical control equipment.

The challenge of this construction was that the combined cycle conversion had to be simultaneously carried out.

These efforts paid off, and commissioning for the gas turbines began on June 6. Subsequently, Units 7-2, 7-1, and 7-3 began commercial operations one after another. This meant successful accomplishment of the first goal, which was to start emergency operations of the gas turbines by July.

Views of Group 7’s Units 1, 2, and 3.

But there was no time to rest. The second goal, building a combined cycle power generation system, was being tackled concurrently. This goal also faced challenges, including securing enough personnel and process delays. However, construction was eventually completed with the cooperation of personnel from Units 1 through 6, manufacturers, and the local fire department. "Despite the many obstacles, we accomplished an unprecedented feat of construction," Uzawa recalls. The project members basked in their hard-earned sense of achievement.

Everyone clapped when the combined cycle conversion was completed.

Kashima’s Lessons About the “Essence of Work”

Reflecting on their struggles during that time, all three men share the common sentiment that the experience of the Kashima Thermal Power Station made them think about the essence of work.

Kamei recalls, “I remember Mr. Sano often telling me, ‘Don’t think first and then run—think while you’re running.’ And he was absolutely right. If we had overthought things back then even the slightest bit, we wouldn’t have finished on time. That’s why we had to fully leverage our knowledge, rally everyone involved, and make split-second decisions. Of course, this was something we could only do during such a situation, but I’m certain that those experiences profoundly shaped my growth.”

Uzawa says, “We were successful because Mr. Kamei grasped the critical aspects of the work. For example, just remembering how to control a device isn’t enough. You need to understand why that control is necessary and how to adjust it according to the situation. Otherwise, you will not be able to make an appropriate decision during an emergency. The emergency power construction work at the Kashima Thermal Power Station was only successful because Mr. Kamei and the other team members continuously asked themselves why things were necessary and honed their skills.”

Uzawa says, “We had full confidence in Kamei's ability to contend with the situation.” Kamei adds, “We were only able to do it because Uzawa brought us together.”

Even as time passes, the lessons from Kashima remain deeply ingrained in each man’s heart. “Kashima’s legacy will live on even after it is decommissioned,” Sano says.

He continues, “The core principle at the time of JERA’s establishment was to simultaneously provide a stable supply of internationally competitive energy and to enhance corporate value. At the same time, JERA’s mission is also ‘to provide cutting-edge solutions to the world’s energy issues,’ including in Japan. JERA’s power stations, including the Kashima Thermal Power Station, will probably take on new and different roles from the past. As we move forward, considering how to best utilize these sites in light of their unique circumstances will be a major theme for JERA.”

As Kashima Thermal Power Station approaches the end of its decommissioning work for Units 1 through 6, it also marks the beginning of a new chapter. (To be continued in the next article)

Sano says, “The key to success will be the ideas of people who know the area.”

RELATED STORIES

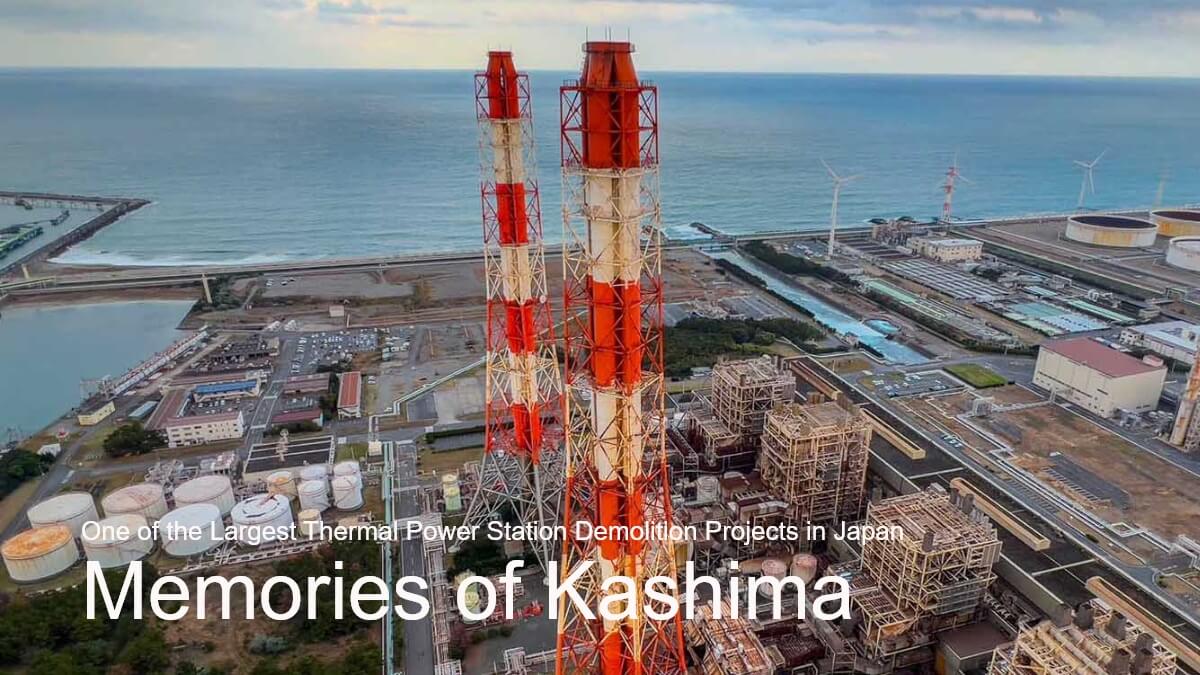

One of the Largest Thermal Power Station Demolition Projects in Japan Memories of Kashima “Responsibilities” Fulfilled by the Top Runner

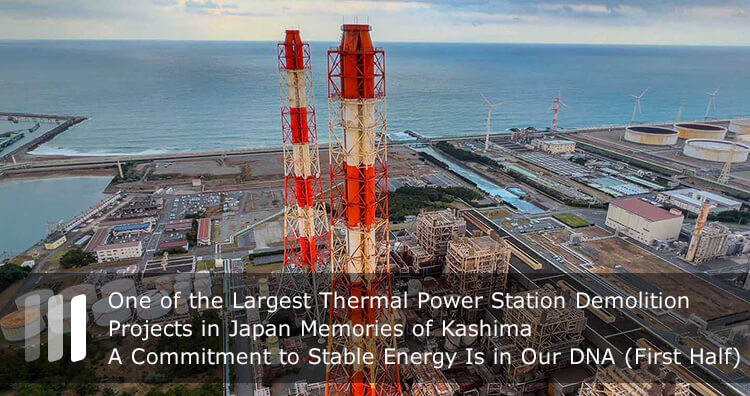

One of the Largest Thermal Power Station Demolition Projects in Japan Memories of Kashima A Commitment to Stable Energy Is in Our DNA (First Half)