The Second Memory

A Commitment to Stable Energy Is in Our DNA (First Half)

27 September 2024

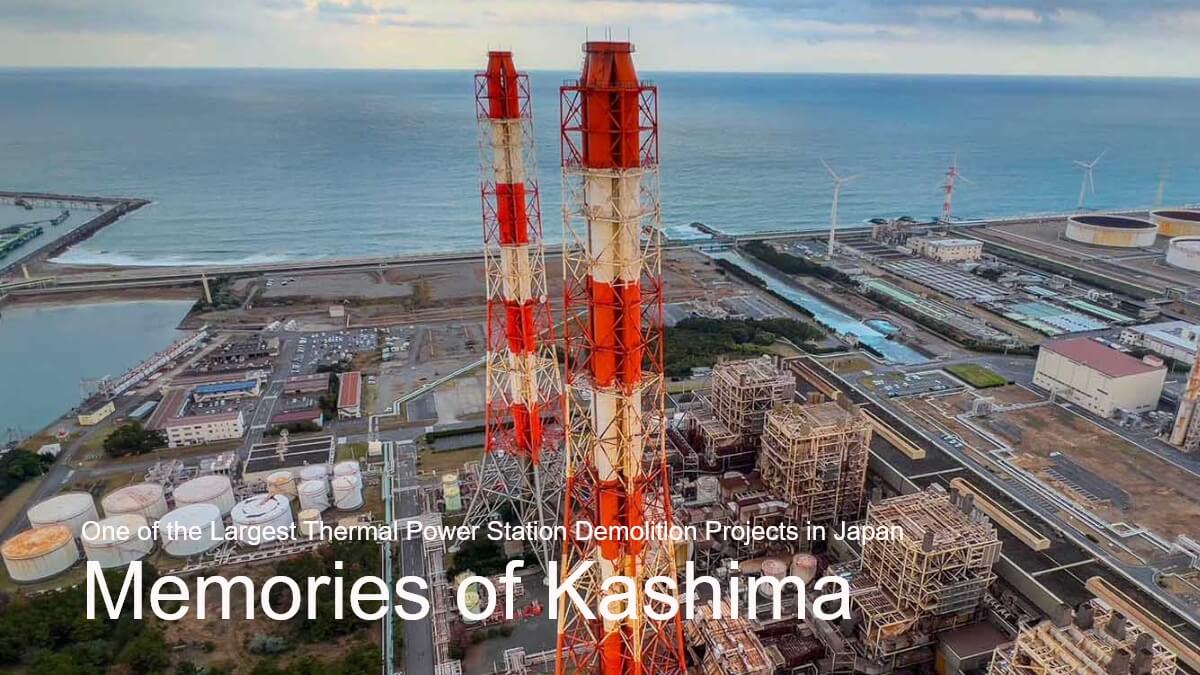

This three-part series takes an in-depth look at the demolition of Units 1 through 6 at Kashima Thermal Power Station. In Part 1, we asked the power station’s General Manager, Hideaki Takayasu, about the background leading to the decommissioning and the goal of the project. Part 2 focuses on the power station’s history.

The primary reason for the decommissioning was aging infrastructure. However, the worn-out state of the power station was also a testament to its long-standing service. The power station was once a driving force behind Japan’s economic growth and served as a crucial lifeline during unprecedented power crises. Behind the scenes were the unflagging efforts of dedicated individuals committed to ensuring a stable power supply. Through their words, we trace the legacy of the Kashima Thermal Power Station.

>> Read Part 1: “Responsibilities” Fulfilled by the Top RunnerINDEX

A Product of the Times: East Asia's Largest Thermal Power Station

Construction of the Kashima Thermal Power Station began in 1968 in the midst of Japan’s period of rapid economic growth. It was during this period that both industry and energy underwent significant transformations, driving a booming national economy that expanded by over 10% annually. Japan’s industrial focus shifted from light to heavy chemical industries, and energy use transitioned from coal to petroleum. Thermal power stations were being built at a rapid pace, leading to thermal power overtaking hydroelectric power in Japan’s energy mix for the first time in nearly half a century.

“The Kashima Thermal Power Station played a role in this period of quick economic growth,” says Toshihiro Sano, who was Chairman of JERA until March 2023 after serving as Director and Vice President of Tokyo Electric Power Co. and President and Chairman of TEPCO Fuel & Power. Sano has long been involved with the thermal power business during his time at TEPCO, and has an enduring connection to the Kashima Thermal Power Station.

He explains, “The Greater Tokyo Area was the hub of Japan’s booming economy at the time, leading to the development of the Keihin and Keiyo industrial zones on Tokyo Bay. Subsequent growth made it necessary to develop areas along the Pacific coast, including in Ibaraki Prefecture.”

Sano says, “I feel a deep personal attachment to Kashima Thermal Power Station.”

As the economy grew, new ports were needed to replace the various ports in Tokyo Bay. This led to the development of the Port of Kashima in Ibaraki. The Kashima coastal industrial zone began to take shape as steel and petrochemical factories clustered in the port area. The Kashima Thermal Power Station was built as the energy source to support this industrial hub.

Sano recalls, “TEPCO positioned Kashima Thermal Power Station as a top performer given its role as the energy provider supporting the growth of the Kashima coastal industrial zone, the hub for many steel plants, factories, and other essential facilities for manufacturing during Japan’s rapid growth. With a total output of 4.4 GW, the power station was said to have the largest output in Asia. Units 5 and 6 each had an output of 1 GW, among the largest in the world at the time. This marked the beginning of the Kashima Thermal Power Station’s history as a world-class power station.”

The construction site for Units 5 and 6 in January 1972.

Panoramic view of the power station in August 1996.

A Reliable, Flexible Presence

As Japan transitioned from a period of rapid growth to stability, there was also a shift in the circumstances surrounding thermal power, including the spread of energy alternatives to oil, such as liquefied natural gas (LNG), higher efficiency thermal power generation facilities, and the rise of nuclear power generation. The role of the Kashima Thermal Power Station changed from being a baseload power source that leveraged its substantial generation scale to a thermal power source that adjusted its output based on electricity demand.

Amidst this sea of change, its trusted presence within TEPCO never faltered. Reflecting on those days, Sano emphasizes, “The power station had an irreplaceable presence.

It could start generating power immediately when necessary, and it could stop just as quickly when there was excess electricity. It was a flexible, adaptable power station. As the person responsible for TEPCO’s thermal power business, I found it absolutely indispensable.”

Beyond its status as the largest power station in East Asia, Sano highlights the capabilities of its talent as key to its success.

“The power station personnel, partner company employees, and everyone else involved felt a strong sense of pride that motivated them to do their part in their respective fields. I believe this was because we worked together as equals with our partner companies. In any industry, the work on the ground goes beyond contracts and other formalities. You have to be on the same level when you think about how to ensure safety and maintain quality. The Kashima Thermal Power Station fostered that kind of relationship.”

Group photo of Sano and operators from the Unit 1 and 2 central control room in August 2008.

This photo of a safety meeting in October 2008 shows the support received from many partner companies throughout the Kashima Thermal Power Station’s history.

A Workplace Where Instincts and Know-How Were Key

Manabu Naito, General Manager of Management unit who oversees power station management, is intimately familiar with the Kashima Thermal Power Station’s history in its heyday. He experienced working as an operator at all six units since joining the company in 1988.

Naito recalls, “My first assignment was in the central control room for Units 5 and 6. Back then, there were about 300 employees at the Kashima Thermal Power Station, and the control room was operated by five teams with eight personnel each. We didn't have automated startup and shutdown back then, so I remember how nervous I felt manually starting and stopping the power generation equipment on weekends.”

Naito now works on power station management as a unit head.

During long-term planned shutdowns, Naito often had opportunities to work in central control rooms other than where he was assigned. He says that one difficulty of the Kashima Thermal Power Station was that all six units had different types of boilers and turbines, each with its own quirks.

“For example, when a malfunction occurred, we had to use sequence diagrams to find the cause. But each machine had a different display, and some were even in English. It was a struggle to figure out the key points for each machine.

Also, during extended shutdown periods, equipment and parts would often seize up and stop working. Those were the kinds of challenges unique to a power station with long-term planned shutdowns.”

Working at the Kashima Thermal Power Station required relying on instincts and know-how gained from experience. That is why Naito says he made it a priority to create clear procedure manuals, emphasizing the importance of explaining and sharing the quirks of each machine.

Skills Passed Down Through Generations of Tradespeople

Naito attributes much of his foundation to the teachings of the senior employees who mentored him. When he joined the company, about 10 new employees were hired each year, and each young worker was assigned a mentor who meticulously taught them the necessary skills.

He recalls, "Automation hadn't taken over yet, so it was a workplace full of skilled tradespeople. I feel that I grew thanks to the guidance of my senior peers, many of whom were highly skilled. Since the job demanded skilled human expertise, it was also a workplace where people were expected to teach others.

Naito on top of the Unit 5 boiler during his first year at the company

A History Shared Alongside the Local Community

Valuing community partnership and environmental preservation have always been basic policies at the Kashima Thermal Power Station.

Naito explains, “Our top concern was the environment. We strictly adhered to regulations for pollutants like nitrogen oxides (NOx) and sulfur oxides (SOx). We operated with measures like introducing low-NOx burners and reducing SOx emissions within fuel tanks to ensure we met those standards.”

There was also active communication with the local community. The power station once welcomed local school field trips. It also provided its grounds and gymnasium for children’s soccer classes and volleyball tournaments for mothers. Above all, the power station contributed to local employment by actively hiring from the area.

Naito says, “I was one of those hires. I joined the company after graduating from a local technical high school. Many local people worked for our partner companies, and it wasn’t unusual to run into former classmates. I believe the Kashima Thermal Power Station significantly contributed to local employment.”

A soccer class held on the power station grounds in October 1997.

A natural education class for local elementary school students held on the power station grounds in June 2010.

For Naito, Units 1-6 of the Kashima Thermal Power Station have represented different stages of his life. Now that the decision has been made to demolish them, he feels conflicting emotions.

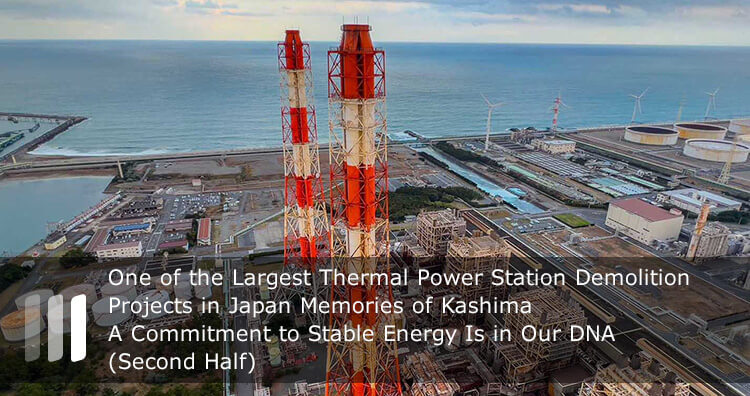

He notes, “The Kashima Thermal Power Station is truly important to me, even if it caused me all kinds of trouble and frustration. I always felt a sense of relief whenever I saw its three iconic smokestacks returning from a business trip. That is why it was so painful to see it fall into disuse and decay. While I feel sad about the decision to decommission it, there's a part of me that thinks maybe it's for the best. Having worked here for so long, I want to make sure the decommissioning is handled properly until the very end.”

Standing in front of the three stacks that he diligently monitored for 36 years, Naito says with a smile, “I want to see everything through to the end.”

When asked when he felt most fulfilled in his work, Naito replied, “It was when I oversaw the equipment and passed it on to the next team without any issues.” His words reflect the long-standing commitment of the power station’s engineers who have prioritized safety, worked in harmony with the local community, and maintained a stable supply of electricity.

But this legacy was majorly tested on March 11, 2011. (To be continued in the second half of the article)

RELATED STORIES

One of the Largest Thermal Power Station Demolition Projects in Japan Memories of Kashima “Responsibilities” Fulfilled by the Top Runner

One of the Largest Thermal Power Station Demolition Projects in Japan Memories of Kashima A Commitment to Stable Energy Is in Our DNA (Second Half)

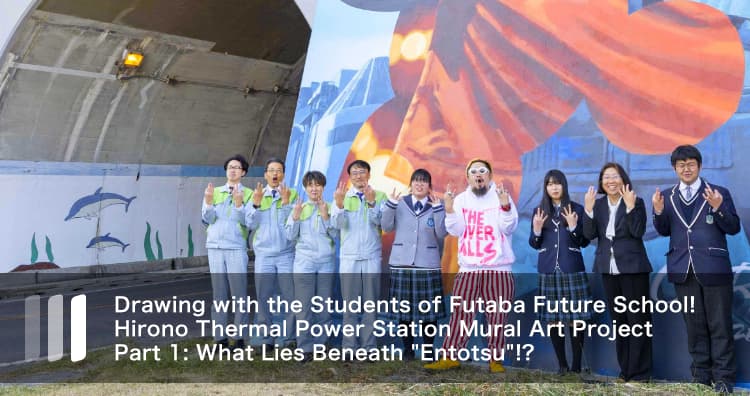

Drawing with the Students of Futaba Future School! Hirono Thermal Power Station Mural Art Project Part 1

On December 21st, a new "symbol of safety" was born within the JERA Hirono Thermal Power Station.