The Zero-Emission Promise of Ammonia

2 November 2023

This summer, temperatures soared across the globe.

In Japan, 128 locations saw record-high temperatures, many setting new consecutive records for extreme heat.

Major cities in North America and Europe also reported record highs, and these rising temperatures have also triggered more intense typhoons and wildfires.

The urgency to address global warming is now undeniable.

Amid this context, JERA, as Japan's largest power company and a major thermal power generation provider, has announced "JERA Zero Emissions 2050" as part of its commitment to achieve net-zero CO2 emissions by 2050. One of these approaches is to start world-leading demonstration tests aimed at "zero-emission thermal power" in a bid to shift from conventional fuels to hydrogen and ammonia, which don't emit CO2 when burned.

Yet, many are voicing: Is achieving net-zero CO2 emissions really feasible? Where will the ammonia be sourced from? Won't the process of producing ammonia itself emit CO2?

To learn more, we sat down with JERA’s Masato Otaki.

INDEX

Ammonia’s Clean Break: The Path to Zero Emissions in Production

─Is thermal power generation without emitting CO2 really feasible?

Thermal power generation, which primarily relies on natural gas and coal, releases the greenhouse gas CO2 when burned.

In contrast, burning ammonia does not produce CO2. By shutting down all inefficient coal-fired power plants by 2030 and gradually transitioning from coal to ammonia as a fuel, we can ultimately achieve thermal power generation without CO2 emissions.

These efforts go hand in hand with increased investment in renewable energy sources like offshore wind power. Our overarching aim is to achieve zero CO2 emissions across JERA by 2050.

─ Is it really possible to replace the coal used in thermal power generation with ammonia?

While there continue to be advancements in power generation technology, a pivotal challenge will be ensuring the vast supply of fuel ammonia that will be required when we adopt it as our primary fuel for thermal power generation.

In March 2024, we will begin combustion demonstration tests that replace 20% of the coal with ammonia at Unit 4 of Hekinan Thermal Power Station in Aichi Prefecture. If that 20% were to be maintained throughout the year, the plant would require an annual volume of about 500,000 tons of ammonia.

To put that in perspective, Japan currently imports around 200,000 tons of ammonia annually. This means that the demand from a single power plant would be more than double the total imports of the entire nation.

As we increase the ratio of ammonia to be burned and extend this approach to other coal-fired power plants, the procurement volume will only grow over time.

But it’s not as straightforward as simply importing the required volume.

Currently, around 200 million tons of ammonia are produced worldwide each year. Of that, only about 10% (around 20 million tons) is traded on the international market.

Moreover, a significant portion of the ammonia currently traded originates from fossil fuels, and its production process emits vast amounts of CO2. Even if we were to import that to replace coal as fuel in our thermal power generation, we couldn’t honestly claim to have achieved net-zero CO2 emissions.

─ So, how can CO2 emissions be reduced to zero?

To truly achieve net-zero CO2 emissions, we need to produce the required amount of ammonia without emitting CO2. We must also minimize CO2 emissions during the transportation and storage processes.

This means we must go beyond just developing ammonia combustion technology; we need to create a new value chain for securing clean ammonia.

We are already nearing the final stages of discussions for participation in several development projects abroad to procure ammonia with reduced CO2 in its production process.

─ How do you produce ammonia while minimizing CO2 emissions?

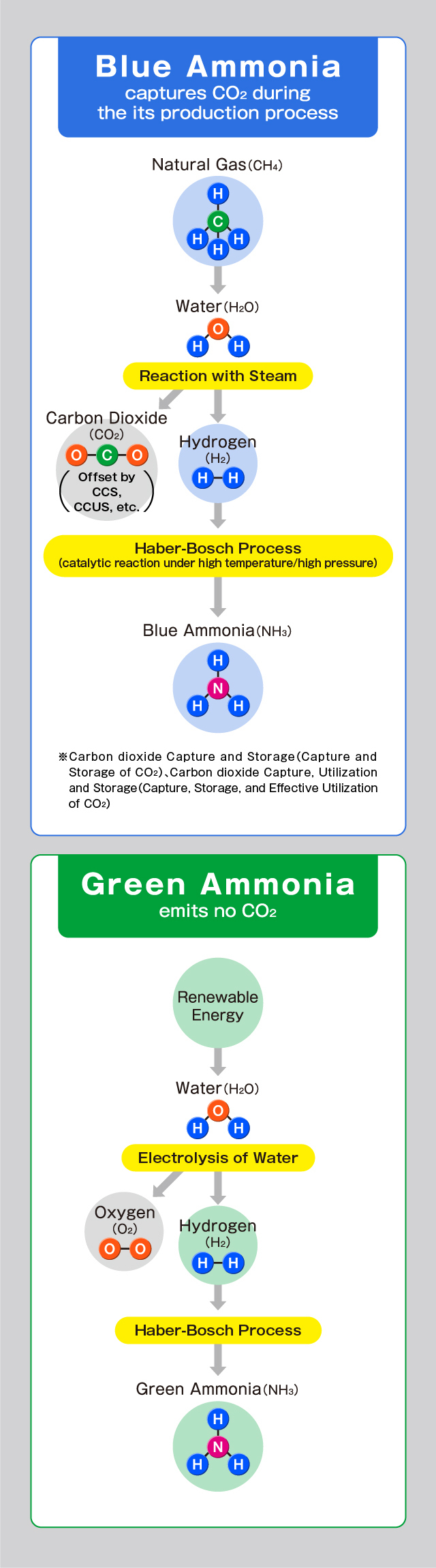

There are mainly two types of clean ammonia that suppress CO2 emissions during production.

The first is green ammonia, which is produced using electricity sourced from renewable energy.

The process involves using hydrogen from water electrolysis and nitrogen separated from the air to produce ammonia, all powered by renewable energy.

While this method does not emit CO2 during production, currently, both the power from renewables and the electrolysis process are costly, making it challenging to use for power generation.

The second type is blue ammonia, which is produced by separating hydrogen and CO2 from the natural gas in what is known as ‘natural gas reforming.’ During this process, the CO2 that is produced is captured and stored, and the hydrogen is synthesized with nitrogen.

We are currently moving forward with blue ammonia production projects in the US, among other countries. The rate of CO2 capture during production has seen rapid improvements, and we anticipate it will exceed 90% in the future.

─ Can't ammonia be produced in Japan?

Manufacturing blue ammonia requires natural gas and CO2 storage sites, while green ammonia production requires a vast amount of land for renewable energy facilities. Unfortunately, Japan doesn't have land suitable for either of these methods.

In this respect, projects in the US have several advantages, including ample land along the Gulf of Mexico, existing infrastructure such as pipelines, and numerous ammonia manufacturers, as well as incentives for hydrogen, ammonia, and renewable energy.

Although the cost of introducing a new energy source must be relatively high, it is expected to decline over the medium to long term as the scale of ammonia production grows and technology advances, similar to solar and LNG.

In regards to green ammonia, the price of renewable energy, which accounts for 50-60% of its production cost, has been dropping year by year, and the performance of the electrolysis equipment required for the production of hydrogen and ammonia is also improving. So, we anticipate a decline in production costs going forward.

Building a Value Chain Essential for Zero Emissions

─ Do you foresee a stable increase in the supply of green and blue ammonia to ensure reliable procurement?

Currently, only Japan and South Korea have plans to directly use ammonia as fuel for power generation.

To ensure a stable supply of ammonia and to make it more affordable, it will be essential to establish a global business that encompasses production, transportation, and storage.

We must take the initiative and actively participate in each of these segments to expand the ammonia market and strengthen our supply chain. This is the “value chain” that JERA has been developing in conjunction with the development of our power generation facilities.

─ How is a value chain different from a supply chain?

A value chain represents a sequence of values. For instance, consider the large-scale development of renewable energy, ammonia production, and transportation from ports via tankers. If you only look at one segment at a time, it is essentially a supply chain.

We believe that by getting involved in each of these segments, we can create a value chain that has the potential to enrich society more broadly than just focusing on a single domain.

Take LNG, for example. If we only have a receiving terminal and wait for the oil majors to deliver the LNG to us for power generation, we will not be able to grasp the cost structure and supply capacity, and we may end up relying on others to procure LNG in an economically efficient and stable. manner.More importantly, that approach wouldn't expand our business reach, nor would it foster innovation. The scope of the value we could offer society would become exceedingly narrow.

By investing in resource development from further upstream and connecting with partners with technical expertise and know-how in transportation and power generation, we can transcend traditional boundaries and create new value and innovative solutions for the world.

Ammonia at the Core of JERA’s Growing Collaborative Framework

─ How far along are you in building this value chain?

Regarding production, we are collaborating with Yara International, the world’s largest nitrogen fertilizer manufacturer, and CF Industries, the world’s premier ammonia producer, to proceed with multiple blue ammonia production projects.

We have formed partnerships with companies like Nippon Yusen Kabushiki Kaisha (NYK) and Mitsui O.S.K. Lines, Ltd. (MOL) for the transportation of the produced ammonia. Together, we are conducting research into the development of large ammonia transport ships and the establishment of safe fuel transportation systems. We are also looking into the development of propulsion engines that could use ammonia as fuel to power these ships.

Additionally, in order to receive and store vast amounts of ammonia domestically, we are working with local partners to study the construction of receiving facilities and the establishment of an ammonia supply system.

─ What kind of business opportunities have become possible through the construction of this value chain?

What we're particularly excited about is the potential for hydrogen-related businesses. Ammonia can be used directly as a fuel as well as decomposed to extract hydrogen.

In the future, a transition to hydrogen is expected to replace fuel in cars, ships, and other vehicles, as well as household gases. When considering the large-scale transportation of hydrogen, we have discussed transporting it in the form of ammonia, which has a smaller volume, before extracting the hydrogen at its final destination.

As the need for hydrogen production, transportation, and storage grows throughout society, expertise in ammonia will become indispensable. That is where JERA’s know-how in ammonia utilization and infrastructure will likely come into play across a wide range of sectors.

We aim to contribute to the decarbonization of a variety of different industries, beginning with power generation.

In fact, we are already collaborating with German energy company EnBW on research into plants that can extract hydrogen from ammonia. We see ammonia as a fuel and chemical component and recognize its potential to transport hydrogen. Together, they offer ways for us to realize business models that utilize ammonia to supply hydrogen.

We have also signed a memorandum of understanding to supply ammonia to another German energy company, Uniper.

Through initiatives such as last year’s international tender for clean ammonia, we have created new ties with companies we had little contact with previously, leading to these new kinds of business collaborations.

Being involved in each segment of the value chain, I genuinely feel that we are seeing opportunities beyond our traditional scope continue to emerge.

─ JERA appears to be diversifying its business beyond the scope of a conventional power company.

The atmosphere at JERA may be quite different now, especially if you compare it to our parent companies, TEPCO and Chubu Electric.

However, amid this change, a profound commitment to energy security remains at our core. That commitment will not change, regardless of shifts in the market or business environment.

While maintaining our value proposition of a stable supply of electricity, we aim to offer society robust solutions that relate to decarbonization. With this in mind, we are working toward achieving our goal of net-zero CO2 emissions by 2050.

Produced by NewsPicks Brand Design

This article is based on a Japanese article produced by NewsPicks Brand Design, which sponsored and translated by JERA.

https://newspicks.com/news/9012214

RELATED STORIES

【A Japan First】CO2 Emissions Free Thermal Power Generation Captures the Interest of the World

Japan’s largest coal-fired power station, Hekinan Thermal Power Station, is located about 40 kilometers south and …

What is JERA’s fuel ammonia initiative, part of its grand plan to eliminate CO2 emissions?

This article is based on a Japanese article produced by Forbes JAPAN BrandVoice, which sponsored and translated by JERA.

Plan A for Decarbonization: Why Is Japan Using Ammonia for Thermal Power Generation?

As JERA continues decarbonization efforts toward achieving zero CO2 emissions by 2050,…