【A Japan First】

CO2 Emissions Free Thermal Power Generation Captures the Interest of the World

23 March 2023

Japan’s largest coal-fired power station, Hekinan Thermal Power Station, is located about 40 kilometers south and an hour’s travel time from Nagoya City in Aichi Prefecture. Opened in 1991, this important regional infrastructure now supplies half of Aichi Prefecture’s electricity and is currently engaged in an effort that is attracting attention from energy professionals in Japan and abroad: thermal power generation that does not emit CO2.

Hekinan Thermal Power Station. The design on the walls is based on a yacht motif.

Among the various types of thermal power generation, coal-fired power generation is particularly high in CO2 emissions and is often singled out as a target in the drive towards decarbonization. But what does it really mean to be “CO2 emissions free”? In this article we take a closer look through our interview with Hisahide Okuda, vice president of JERA, Japan’s largest power producer, which operates the Hekinan Thermal Power Station.

INDEX

Decarbonization is the Price of Entry to the Global Market

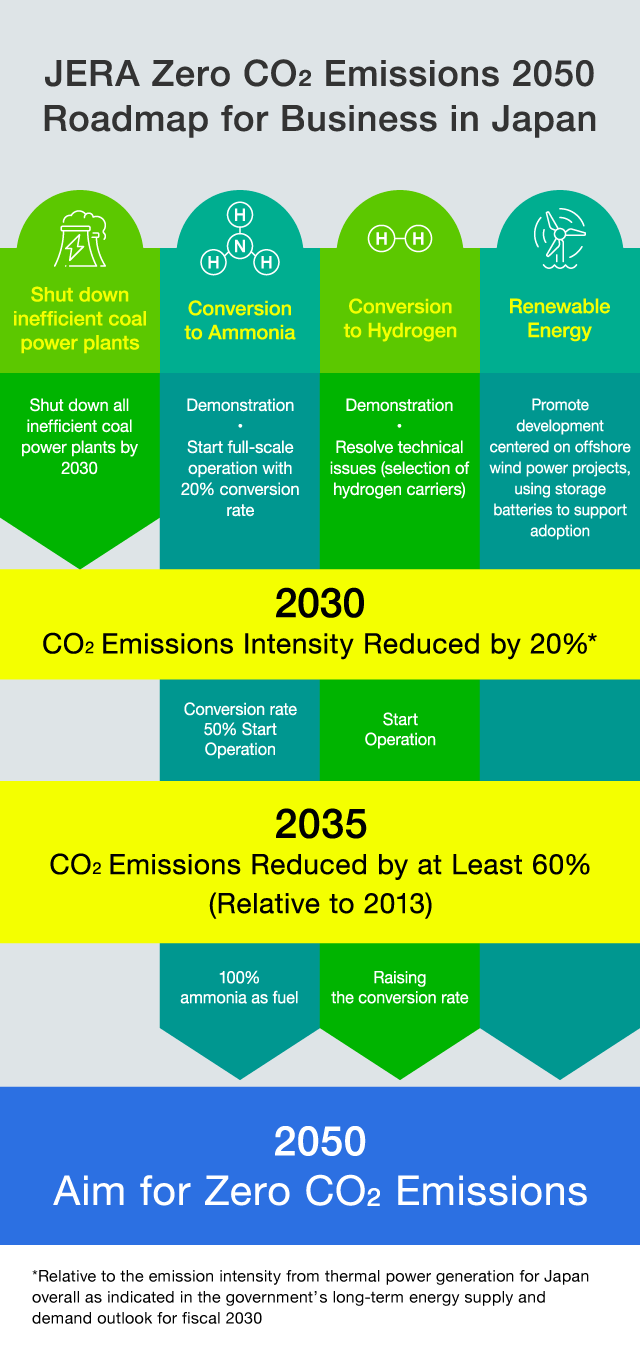

On 26 October 2020, the government of Japan announced its commitment to achieve “carbon neutrality”—that is, net-zero greenhouse gas emissions—by 2050. About two weeks earlier, on 13 October, JERA announced its “JERA Zero CO2 Emissions 2050” long-term vision to gradually bring CO2 emissions close to zero by 2050.

JERA was created through the 2015 merger of the thermal power and fuel businesses of TEPCO and Chubu Electric Power Company, and accounts for about half of Japan’s thermal power output, so the company’s declaration of intent to eliminate CO2 emissions was a significant milestone in Japan’s energy shift. Hisahide Okuda, the JERA vice president who led the development of this vision, describes the commitment to decarbonization as “the price of admission to engaging in the energy business on a global scale.”

Energy companies around the world, especially in developed countries, are being asked to define their approach towards the environment. It is no exaggeration to say that without doing so, they can no longer form partnerships with or receive financing from other companies globally. As a power generation company whose main business is thermal power generation, and as a global company set to further expand its overseas business, a commitment to decarbonization was absolutely essential for us. (Okuda)

Thermal power generation burns coal, oil, and liquefied natural gas (LNG) to produce electricity. Fuel for thermal power generation can be stably procured even in resource-poor Japan and, unlike renewables such as solar and wind power, thermal is unaffected by natural conditions and does not require large tracts of land.

Thermal is one of the most important power generation methods, accounting for approximately 80% of Japan’s current energy mix and, according to the Strategic Energy Plan announced by the government, expected to make up approximately 40% of the energy mix in 2030. It does involve high CO2 emissions, but JERA aims to gradually reduce them to zero and ultimately generate CO2 emissions-free thermal power. At the same time, JERA will also promote renewable energies that complement zero-emission thermal power in promoting carbon reduction and decarbonization.

JERA is working to reduce CO2 emissions through both zero-emission thermal power and renewable energy.

Creating CO2 Emission-Free Thermal

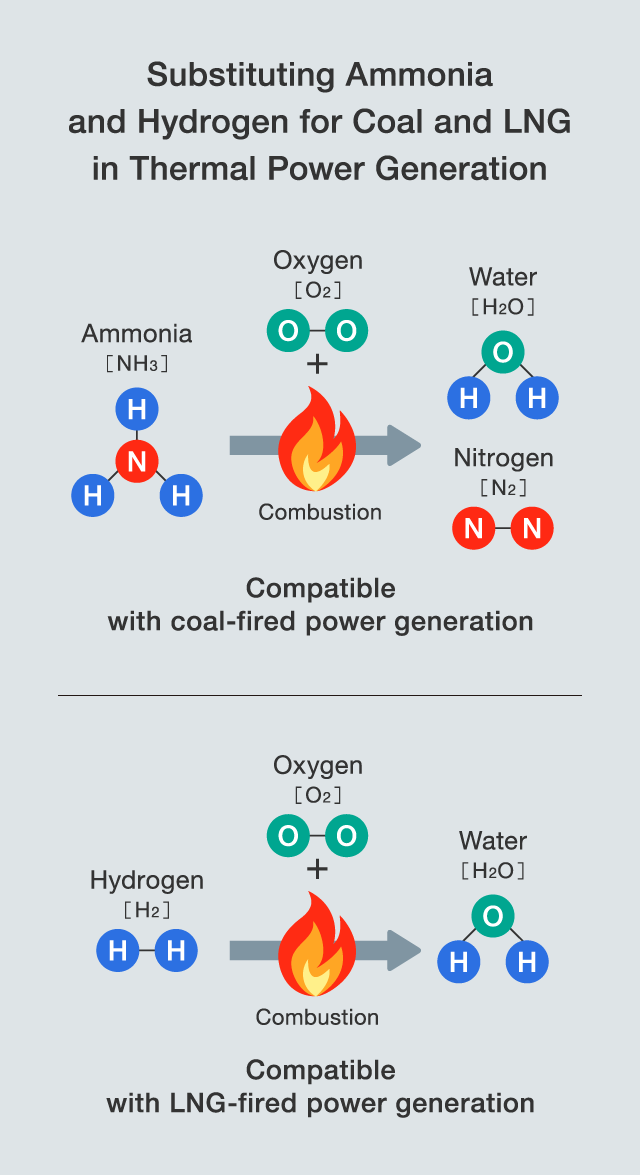

So, how exactly will zero-emission thermal power be achieved? The key is ammonia (NH3) and hydrogen (H2). As their chemical formulas show, neither contains carbon (C). This means that when they are burned and combined with oxygen, no CO2 is produced.

The roadmap drawn up by JERA for achieving zero emissions by 2050 involves modifying existing coal- and LNG-fired thermal power generation facilities to “combust” chemically compatible ammonia or hydrogen.

Demonstrations of this process are underway at the Hekinan Thermal Power Station, mentioned at the beginning of this article. In 2021, small-scale combustion with coal and ammonia began in collaboration with IHI, a major heavy industry company. In 2023, demonstration testing at a rate of 20% with ammonia will be conducted and, based on the results, full-scale operation will begin with the substitution rate gradually increased with the goal of switching to dedicated firing in the 2040s. The higher the converting rate, the greater the reduction in CO2 emissions.

JERA’s plan is to establish the world’s first large-scale ammonia combustion technology through these demonstrations at the Hekinan Thermal Power Station, and then to apply this technology to other thermal power stations in Japan and abroad.

Why Bet on Ammonia?

Hydrogen has been seen as a promising next-generation clean fuel, attracting interest from a wide range of fields as a potential fuel for cars and ships or an energy source for power generation. On the other hand, there are few examples of ammonia being used as an energy source, so why has JERA focused on ammonia? There are several reasons, but the first and most important is the ability to utilize existing technologies and facilities.

Normally, when dealing with a new fuel, it is necessary to build new power generation facilities that are compatible with it, but ammonia combustion requires only slight modifications to existing power generation facilities. (Okuda)

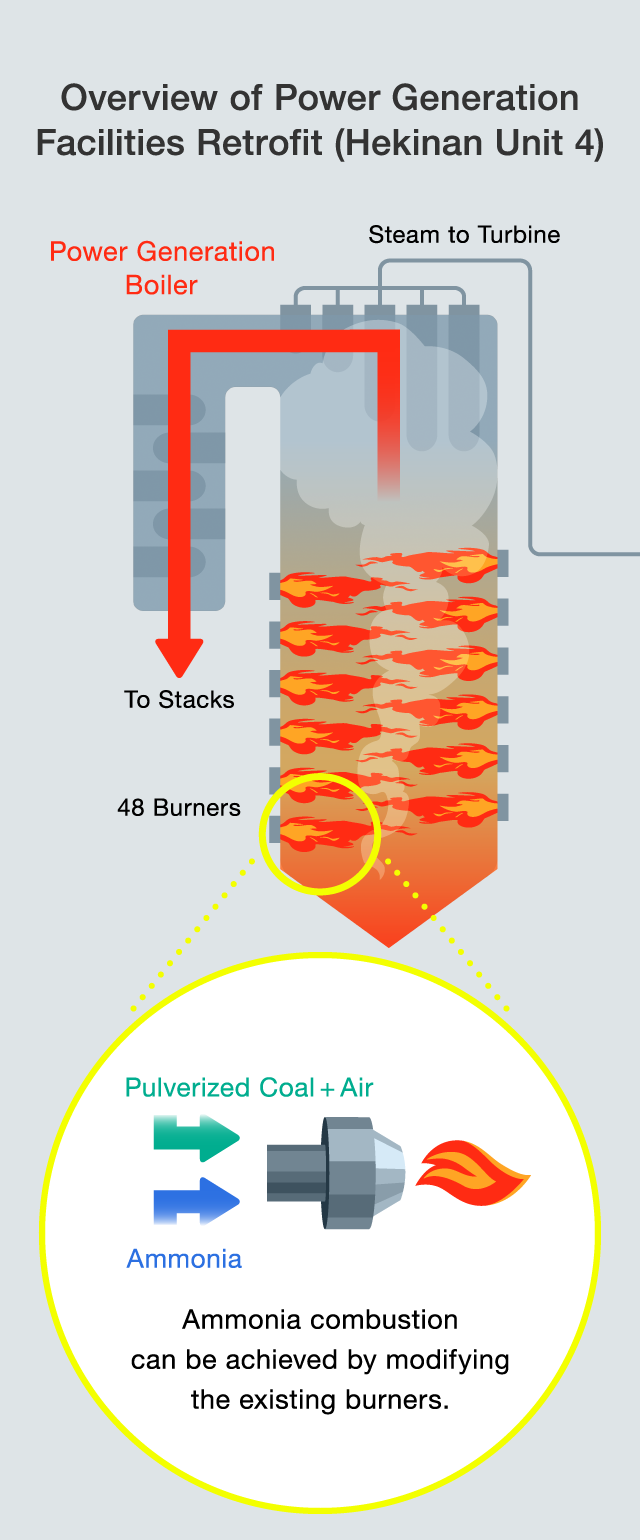

Coal-fired power plants have a boiler—a huge 80-meter-high rectangular structure—into which burners are inserted to burn the coal. The resulting heat is used to boil water and convert it into steam, which turns the blades of a generator’s turbine to produce electricity.

Ammonia combustion can be achieved by simply changing the burners slightly. Separate tanks and piping for storing ammonia are required, but the rest of the power generation equipment and transmission lines require little modification. As Okuda noted, compared to new power plants that entail huge costs and take a long time to prepare and construct, “zero-emission thermal power” is a relatively low-cost, speedy, and effective means of decarbonization.

In addition, Japanese coal-fired power plants are accustomed to handling ammonia. Ammonia is already used at thermal power stations for denitration, which breaks down nitrogen oxide (NOx), a toxic substance contained in the exhaust gases of thermal power stations, into nitrogen (N2) and water (H2O). NOx is a cause of photochemical smog, but after problems such as the pollution of the 1970s, Japan has had treatment technology that leads the world. JERA is confident that it can use existing technology to deal with the NOx emitted when ammonia is burnt.

Environmental equipment that removes nitrogen oxides, sulphur oxides, and other substances from exhaust gas.

Ammonia tank for denitration.

The Eyes of the World are on Hekinan Thermal Power Station

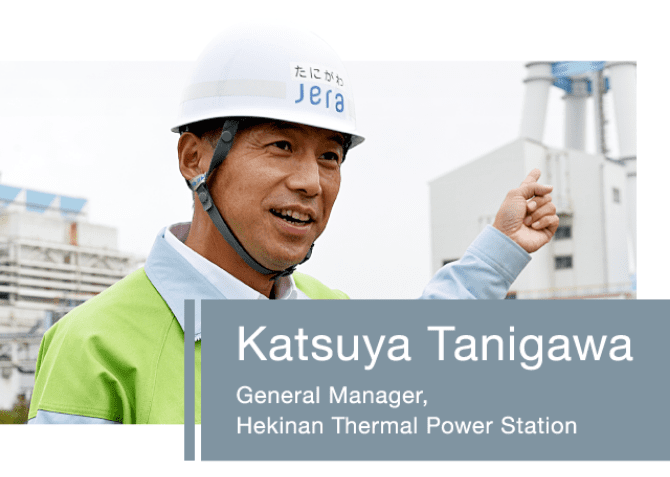

Katsuya Tanigawa, General Manager of Hekinan Thermal Power Station, recalls how happy he was when he heard about the ammonia project. As mentioned above, coal-fired power plants emit particularly high levels of CO2. For more than 15 years, Hekinan Thermal Power Station has been making cutting-edge efforts to reduce CO2 emissions by combusting coal with woody biomass and carbonized sludge, a substance produced in sewage treatment. Nevertheless, this still results in a certain amount of CO2 being produced. Tanigawa was proud of the plant’s role in providing a stable supply of electricity but had been feeling a bit sheepish in the face of the global movement towards decarbonization.

It was at just that juncture that the demonstration project came in, so all the staff, including myself, felt a sense of responsibility and pride. We felt this was the start of a huge effort that would leverage unique Japanese technology. (Tanigawa)

Hekinan Thermal Power Station currently has five power generation facilities. Units 1 through 3, which each have an output of 700 MW, were built in the early days of the plant, while Units 4 and 5 each have an output of 1,000 MW. The coal used for power generation is transported by transport ships from countries such as Australia and Indonesia and stored in heaps in a huge coal storage area that measures approximately 300,000 square meters—roughly the equivalent of six Tokyo Domes. The coal is then sent to Units 1 through 5 on belt conveyors.

To pursue energy security and lower fuel costs, a combination of several types of coal is used. Hekinan Thermal Power Plant has handled around 160 types of coal so far.

Coal heaped in piles. The water pool at the base of the coal piles forms because the coal is regularly sprayed to keep it from blowing away.

Coal is transported to each power plant on the long belt conveyor at the center of the picture.

At the time of our reporting in November 2022, a small-scale 0.02% ammonia demonstration test had just been completed at Unit 5. As noted above, no modifications were made to the boiler itself. Just two of the 48 burners plugged into the boiler were modified to carry out ammonia combustion. The purpose of the test was to check the effects of different materials and the parameters required for demonstration burners, with the main objective of developing a demonstration burner for use in the large-scale 20% ammonia demonstration test coming up in 2023. Tanigawa said, “We were able to collect the necessary data during the small-scale tests and confirmed there were no problems at all with the operation of the power generation facilities. Now we’re getting ready for the world’s first 20% ammonia ammonia demonstration test.”

Turbine for generating electricity (Unit 5).

The start of demonstration test in 2023 will come a year earlier than originally planned given the steady progress made in demonstrations so far. Many media and energy professionals from home and abroad visit Hekinan Thermal Power Station to see the site of the world’s first demonstration for themselves. “It makes me proud that so many people expect so much of us,” said Tanigawa, who closed our interview by expressing his desire to “move forward with the demonstration step by step, placing the highest priority on the safety of our co-workers and people in the local community.”

The planned construction site for an ammonia tank to be used for demonstration purposes (near the crane in the foreground of the photo).

Another Barrier to convert to Ammonia

Preparations to ammonia conversion are underway as part of achieving zero-emission thermal power generation. However, there is one more hurdle to overcome before ammonia can be put into full swing: securing the ammonia.

Most of the ammonia currently consumed in Japan —approximately 1 million tons per year—is put to industrial use. If 1 million kW of coal-fired power is converted to 20% ammonia, 500,000 tons of ammonia will be required annually. In other words, half of the ammonia currently used in Japan annually would be taken up by Hekinan Thermal Power Station Unit 4 operating at a 20% ammonia ratio. Being able to secure vast amounts of ammonia will be a key condition for increasing the ammonia rate going forward. Okuda predicts that “as it was with LNG in the early days, once the value of ammonia is recognized the hurdles to procurement will fall.”

LNG carrier Soshu Maru.

LNG is now an essential fuel for many countries, but natural gas was originally a discarded by-product of drilling for oil. About 50 years ago, several countries, notably Japan, started using it as a fuel. As demand rose, the supply chain stabilized and costs fell. In the same way, when there is demand for large quantities of ammonia, supply will naturally increase to meet it. (Okuda)

In fact, after JERA announced its concept for ammonia combustion, it received offers for fuel procurement from all over the Middle East, Asia, Australia, and other countries. In February 2022, the company held an international tender for the procurement of ammonia and is currently in discussions with several operators to work out a concrete deal.

Meanwhile, collaborations with Japanese companies are also underway. In November 2022, JERA announced that it was considering collaborations with Kyushu Electric Power, Chugoku Electric Power, Shikoku Electric Power, and Tohoku Electric Power in areas including joint procurement of hydrogen and ammonia for use as fuel in power generation. That same month, JERA also announced collaborations with NYK Line and Mitsui O.S.K. Lines (MOL) and is now considering the specifics of building and expanding supply chains with both companies based on the development of large ammonia carriers and the establishment of safe transport systems.

Centered in Asia, Reaching Out to the World

JERA is taking steps to achieve zero emissions while overcoming various challenges. The company looks ahead to the “overseas expansion” of the solutions it has developed in Japan. For example, Southeast Asian economies are growing fast and their demand for electricity is increasing. In addition, many coal-fired power stations in the region have only just been built.

In the future, not only developed countries but the whole world will have to commit to zero CO2 emissions. In this context, we believe that the need for ammonia, which requires no major modifications to be made carbon-free, will only grow. (Okuda)

In addition, European countries that have previously committed to reducing their reliance on thermal power are now, in the wake of events such as Russia’s invasion of Ukraine, taking another look at thermal as a realistic means of generating power. JERA has already been consulted about ammonia by operators in Europe as well as Asia. Until now, it has been taken for granted that thermal power produces CO2. But this may now be a thing of the past. An effort to overturn such received wisdom is now underway in Japan.

Produced by NewsPicks Brand Design

Edited by Tomoka Takahashi

Designed by Kumi Kotani

Photographed by Kazushige Mori

This article is based on a Japanese article produced by NewsPicks Brand Design, which sponsored and translated by JERA.

https://newspicks.com/news/7878973

※ May 10, 2024, some wording was changed.

RELATED STORIES

A new era for energy. Where does electricity come from?

“I wanted to build a globally competitive company.”These are the words of Yukio Kani, one of the key people behind…

Connecting to the Next Generation: University Students Consider the Future of Energy

It's 10:00 a.m. on Friday, February 10, 2023. The air is humid in the Kanto and Chubu regions due to a southern …

Making the Most of Reclaimed Vehicle Batteries: Power Storage Solutions to Promote Renewable Energy

In February 2023, we visited Yokkaichi Thermal Power Station in the city of Yokkaichi, Mie Prefecture.