Zero-Emissions Thermal PowerSustainability

Zero-Emissions Thermal Power

As stated in JERA Zero CO2 Emissions 2050, we will rise to the challenge of achieving decarbonization by combining renewables with zero-emissions thermal power.

Generating power with solar, wind, and other renewables involves no greenhouse gas emissions, and the energy sources are available in perpetuity. Thus, they should be adopted whenever and wherever possible to prevent global warming and use energy most effectively. However, output from these natural energy sources fluctuates widely due to season, weather, and other natural factors, making it difficult to ensure a stable power supply when and where it is needed. To mitigate this problem, we leverage one of the defining characteristics of thermal power generation: adjustable output.

Toward that end, we will introduce zero-emissions thermal power by replacing conventional fuels like coal and LNG with ammonia and hydrogen, which emit no CO2 when combusted. Our aims with this shift are to complement renewables with thermal power and vice versa and to achieve carbon neutrality by 2050.

Utilizing Ammonia and Hydrogen

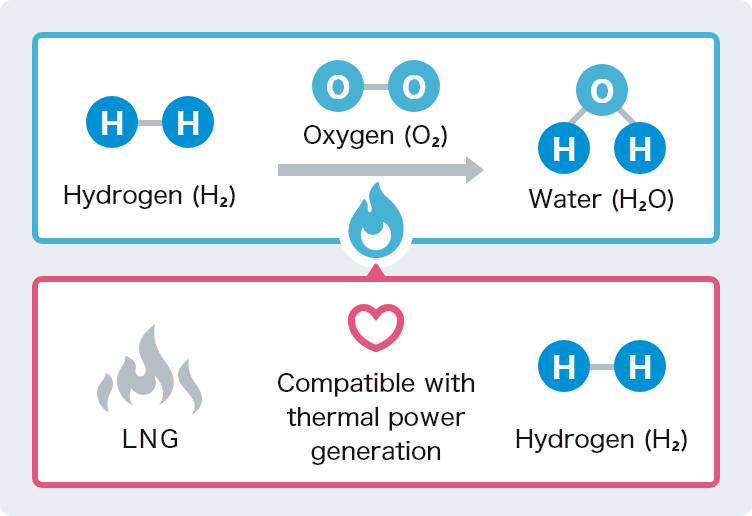

Hydrogen is often called the ultimate clean energy, garnering attention worldwide for its completelack of carbon emissions.

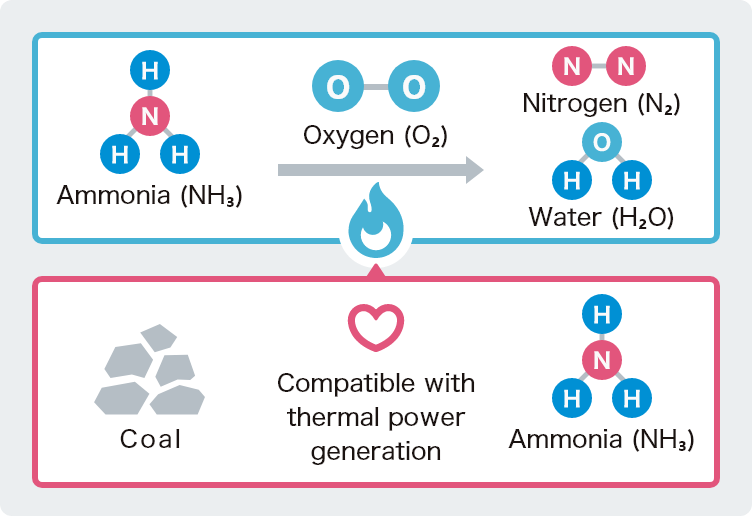

Ammonia, a hydrogen-based form of energy, is an energy carrier that efficiently transports and stores hydrogen energy. Ammonia is an apt fuel for clean thermal power generation because it emits no CO2 when combusted, meaning we can use it in its normal state. Accordingly, it should become commercially viable as a fuel for thermal power generation in short order.

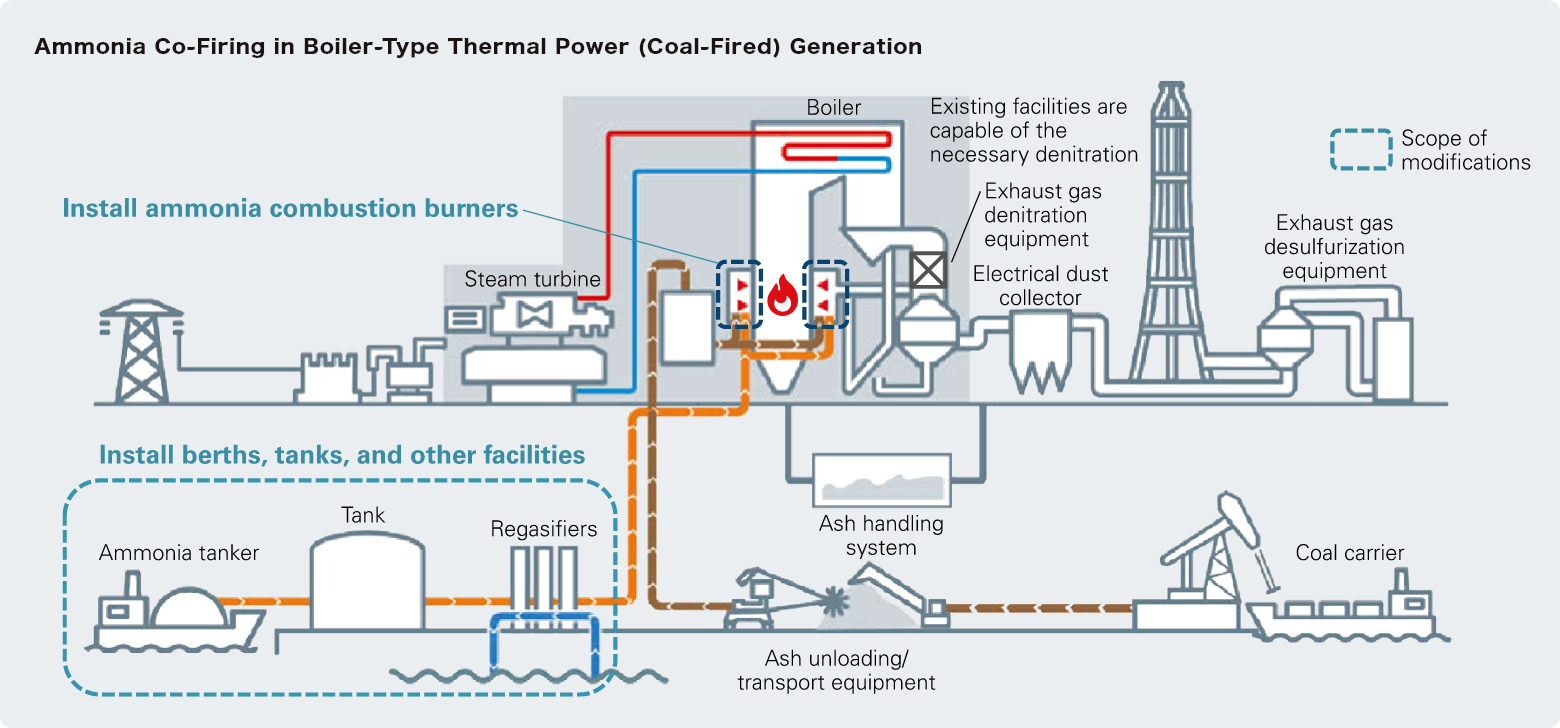

Using Existing Facilities to Reduce Costs and Expedite Installation

We believe that gradually replacing the fuels used in thermal power generation facilities with ammonia and hydrogen is an effective option for reducing costs and deploying zero-emissions thermal power rapidly while maintaining a stable power supply.

Thanks to their compatibility in terms of combustion speed and quantity of heat, we plan to use both ammonia and hydrogen in our power generation. Ammonia is compatible with the boiler-type systems used in coal-fired thermal power, while hydrogen is compatible with the gas turbine-type systems used in LNG-fired thermal power.

Notably, the Japanese government’s Sixth Strategic Energy Plan also calls for the promotion of co-firing with non-carbon fuels and other thermal power generation efforts by 2030 while ensuring facility capacity is sufficient for a stable supply. And for the first time, the plan includes hydrogen and ammonia in its composition of power sources.

Ammonia Co-Firing in Boiler-Type Thermal Power (Coal-Fired) Generation

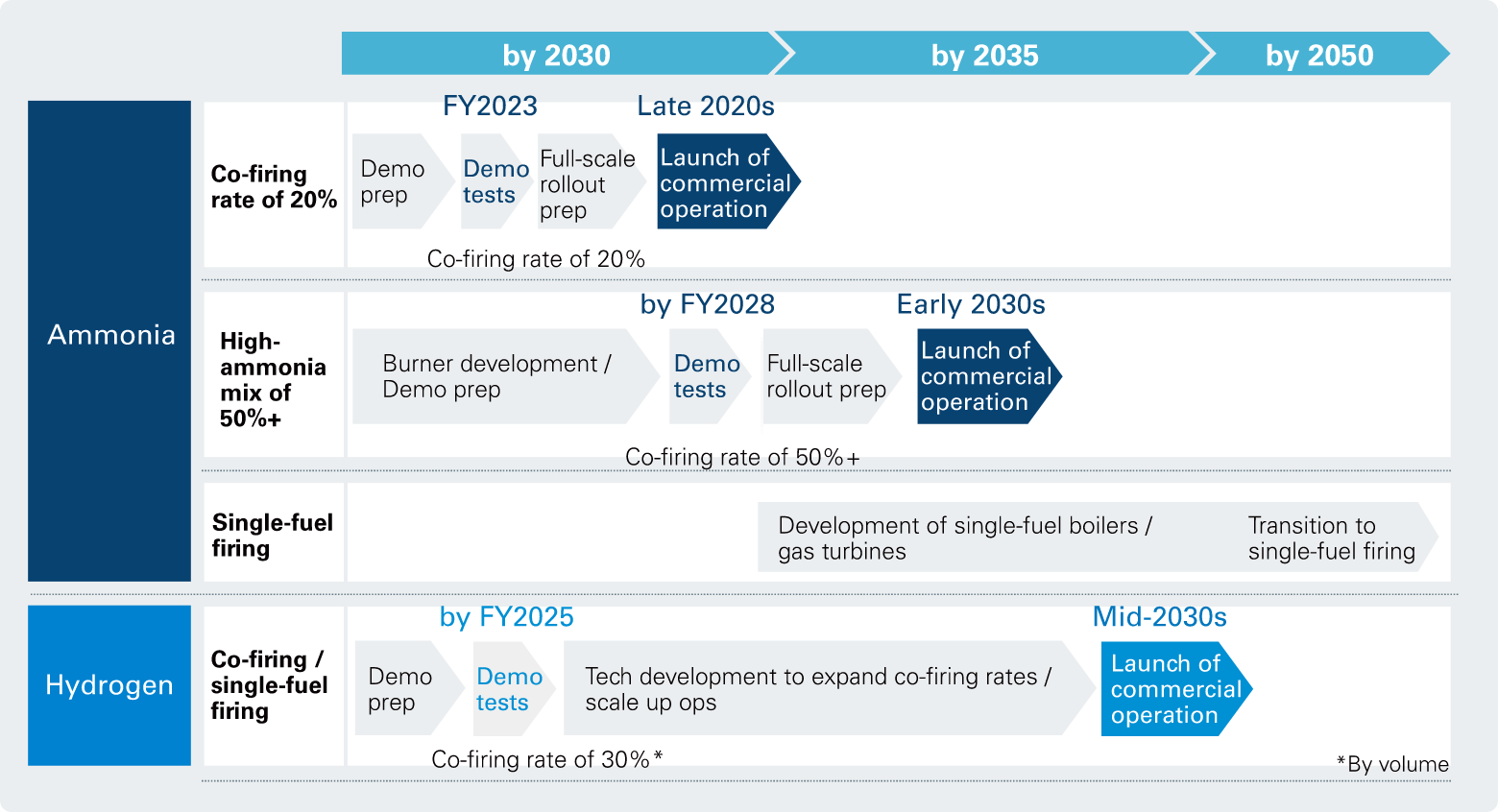

Ammonia and Hydrogen Introduction Plan

In FY2023, we plan to start demonstration tests in which we replace 20% of the existing fuel mix with ammonia at Hekinan Thermal Power Station Unit 4. We will increase the ammonia component to at least 50% by FY2028 and conduct more demonstration tests with the aim of making high-ammonia mixes (50%+) commercially viable in the early 2030s.

We also plan to conduct demonstration tests with a co-firing rate (by volume) of 30% hydrogen at our gas turbine-type LNG-fired thermal power plants by FY2025 to make hydrogen mixes commercially viable in the mid-2030s.

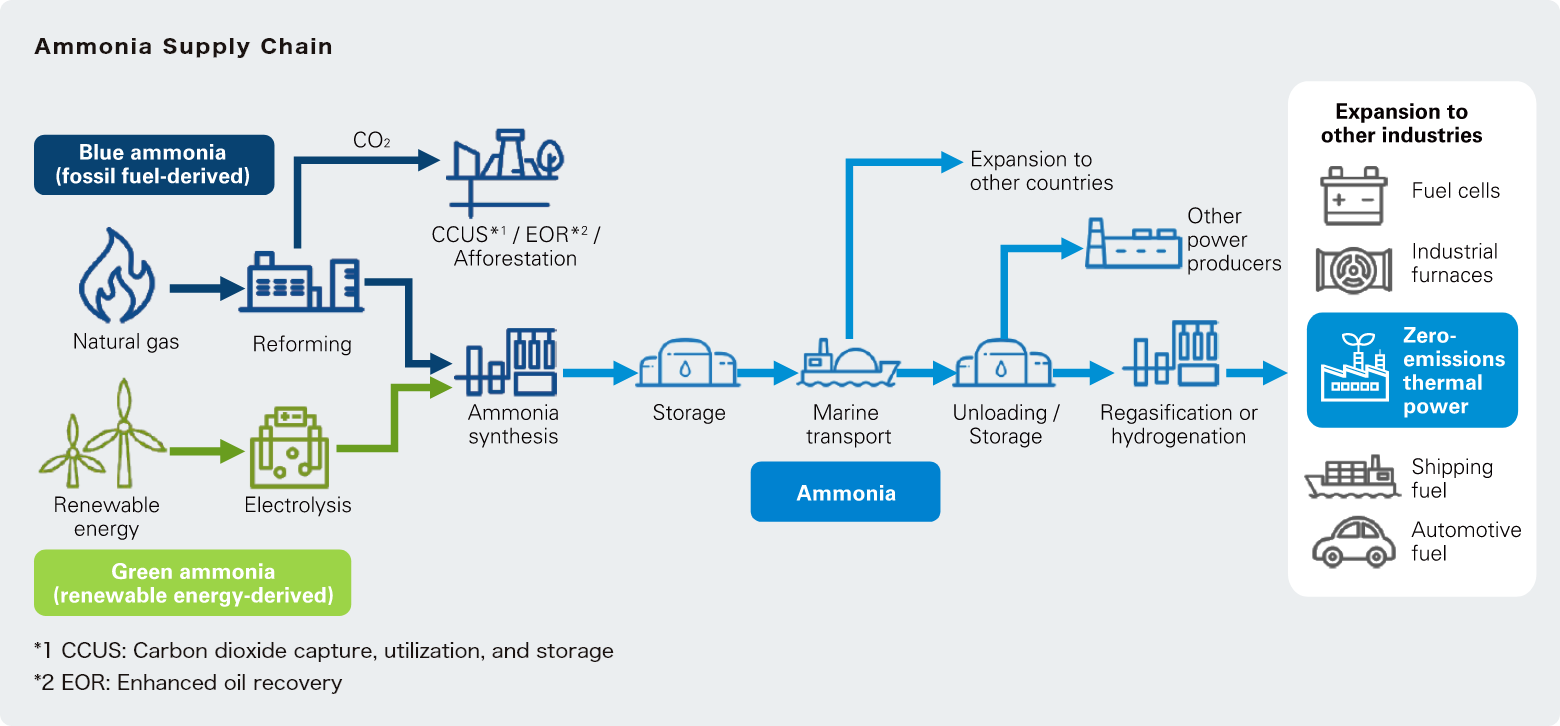

Building a Supply Chain

If we replace 20% of the fuel at a 1 GW thermal power plant with ammonia, we would need roughly 0.5 million tons of ammonia each year, equivalent to half the current annual consumption in Japan, which is mainly for industrial use and fertilizers.

Therefore, it is essential to establish a new supply chain for fuel ammonia to ensure a reliable supply for thermal power generation. We will also consider expanding our business domain beyond power generation to include the development of clean fuels for other industries.

The process of producing ammonia and hydrogen will be one of the keys to unlocking a decarbonized society. We are exploring a wide range of possibilities, including green ammonia and hydrogen produced via electrolysis of water with electricity derived from renewables, as well as blue ammonia and hydrogen, which store CO2 separated and captured in fossil fuel-powered manufacturing processes.

Ammonia Supply Chain

- CCUS: Carbon dioxide capture, utilization, and storage

- EOR: Enhanced oil recovery

Expansion into Asia

We believe that zero-emission thermal power with ammonia and hydrogen is a realistic approach to achieving both a stable power supply and decarbonization. By offering this approach as one of our solutions to people in burgeoning economies in Asia and the rest of the world, we hope to contribute to the power supply and pursuit of decarbonization that underpins economic growth in those countries and regions.

Promoting and Expanding Green Fuels by Leveraging the Strengths of the Entire Value Chain

Together with many partners, JERA has established a full value chain—from power generation to gas field development, liquefaction, and fuel transport and storage—to realize stable and economical procurement of LNG. We will apply this concept of full value chain utilization to hydrogen and ammonia to drive the promotion and expansion of green fuels.

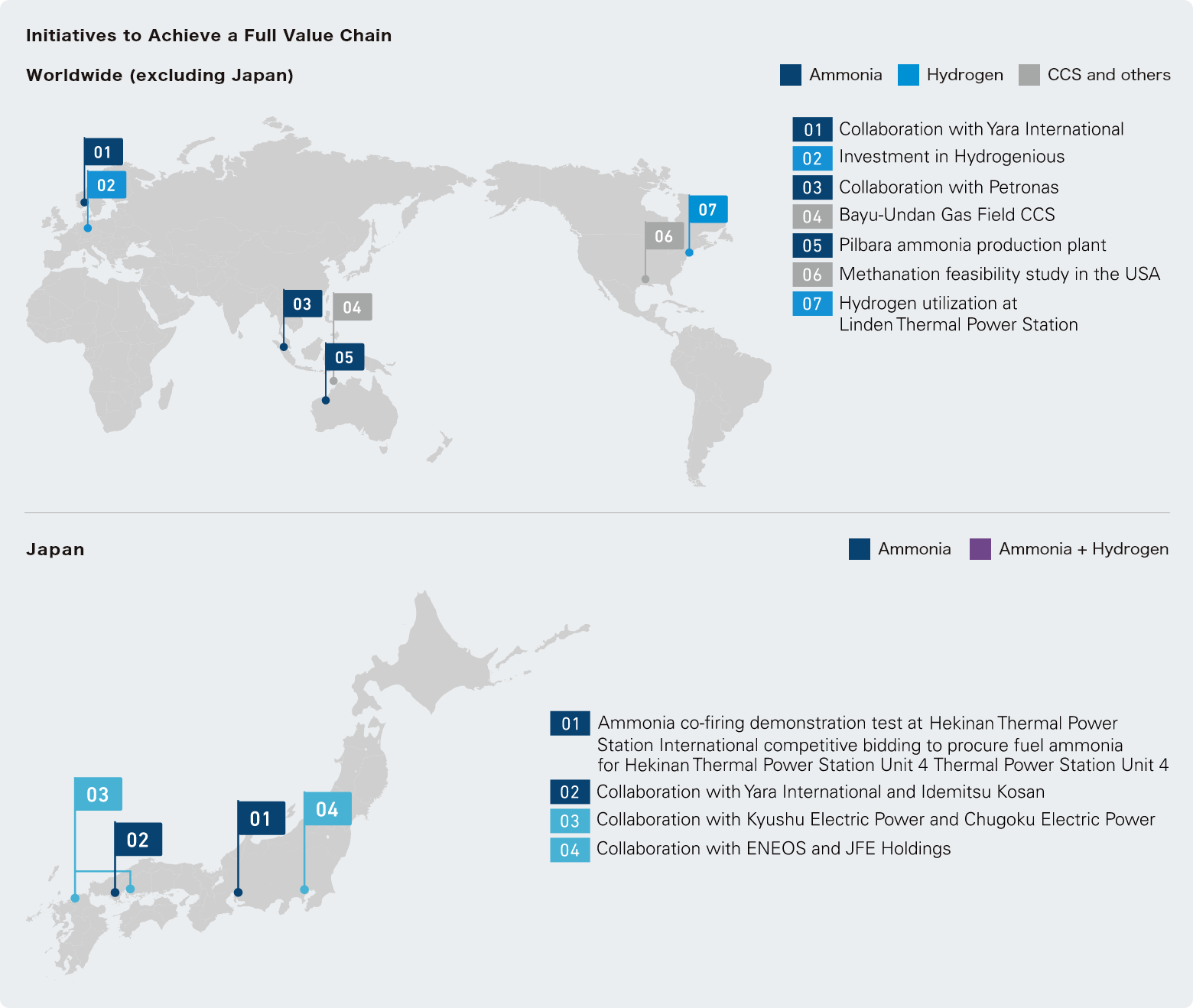

Initiatives to Achieve a Full Value Chain